Automatic Screw Feeder with servo nut runner

CM-30T-SERVO

SEALS CM-30T-SERVO adopt high accurancy and low reaction force servo nut runner. It can provide the detailed information of every screw fastening.Designed for speed, stability and convenience. It could give warming currently when the fasten is out of setting patterm. And, it will come out a table list for your fastening process.

Meanwhile, you could also control the angle and speed of drive to reach the fastening quality requirement.

Most of all, you could organized a several fasten series as one job which cannot be done by electric screwdriver.

The jaw is customized by particular screw and working environment to provide a stable operation.

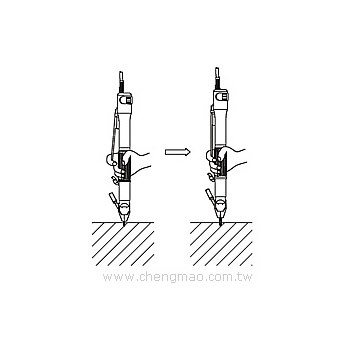

The lever-activating design shall meet the ergonomics and laborsaving requirements.

Simply press the lever and the Screwdriver will complete the screw fastening automatically.

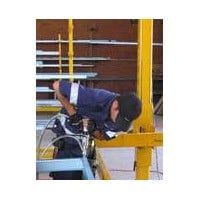

With TA-300 torque reaction arm, it provides a steady vertical alignment for screw fastening. It enhances your product assembly quality and reduce the fatigue of operator.

Especially for the high torque shut-off screwdiver, it could keep the more stable performance of torque driver than hand-held.

Nickname

Automatic Screw Feeding Machine with servo nut runner

Features

1. The lever-activating design shall meet the ergonomics and laborsaving requirements.

2. Simply press the lever and the Screwdriver will complete the screw fastening automatically.

3. Automatic feeding to completely save the screw picking and moving action.

4. Applicable for 2.5mm ~ 6.0mm screws.

5. It provides faster operating speed up to 20 ~ 30 screws per minute.

6. The torque-controlled screwdriver is used to improve the fastening quality for the customer.

7. It uses Japan-made electric / pneumatic screwdrivers.

8. Fiber Optic control intellectual-type feeding, saving power while avoiding short supply.

9. The bit pushes the screw for fastening automatically. It prevents the jaw from contacting the surface of the work-piece; thus it will neither rub the product nor produce too much stress.

10. It is equipped with Spring Balancer to provide load free operation experience.

11. You may also select TR-350A, TR-350AE, TR-650A, TR-650AE, TA-300, TA-600, TM-6, THA and THB to provide a variety of accessory combination according to actual work need so as to achieve high-performance fastening quality.

Specification

- Voltage: 220V, Single Phase

- Air Pressure: 5.5 kg / cm² / 85PSI

- L / W / H: 35 / 25 / 38 cm

- Net Weight / Gross Weight: 23 kg / 31 kg

- Capacity: 30 pcs/min.

- Torque: Refer to screwdriver capacity

- Volume: M3 x 15 2000 pcs

- Driver: Estic branded Nut Runnerr

Available Screw Chart

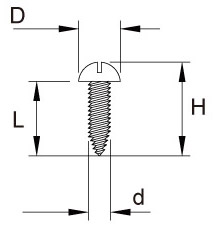

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

(Note) Special specification screws not included in this table also can be used. For details, please contact a serviceperson of this Company.

| Pan Head Round Head | Flat Head Oval Head | Binding Head | Truss Head | Max. L Dimension (L) | ||||

|---|---|---|---|---|---|---|---|---|

| Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | |

| 4.6 | 8 | 4.9 | 8 | 5.2 | 9 | 12 | ||

| 4.5 | 8 | 5.0 | 8 | 5.3 | 8 | 5.7 | 10 | 16 |

| 5.5 | 9 | 6.0 | 9 | 6.3 | 9 | 6.9 | 11 | 20 |

| 6.0 | 9 | 7.0 | 10 | 7.3 | 10 | 8.1 | 12 | 22 |

| 7.0 | 10 | 8.0 | 11 | 8.3 | 11 | 9.4 | 13 | 22 |

| 8.0 | 11 | 9.0 | 12 | 9.3 | 12 | 10.6 | 14 | 22 |

| 9.0 | 12 | 10.0 | 13 | 10.3 | 13 | 11.8 | 15 | 22 |

| 10.5 | 13 | |||||||

Accessory

Extension Hopper: Part No. RH-1 (Optional)

- Gallerys

- Related Products

Automatic Screw Feeder with Lever-Activating screwdriver set

CM-30T

SEALS CM-30T Automatic Screw Feeder adopt ergonomic design of screwdriver set. The operator only need to simply trigger the lever of driver and the bit will push downward and fasten screw automatically. SEALS CM-30T reduces the downward press stroke of operator to enhance the productivity and reduce fatige . Meanwhile, the jaw will not press the surface of work-piece hardly so that it could also protect the coating of products. For automation purpose, SEALS automatic screw feeder also could be integrated into automation machine such as XY Table, SCARA robot, 6 axis ROBOT and any customized auto assembly machine, etc. And, its automation version also can provide relevant signals and receive control signal for communicate with major control system.

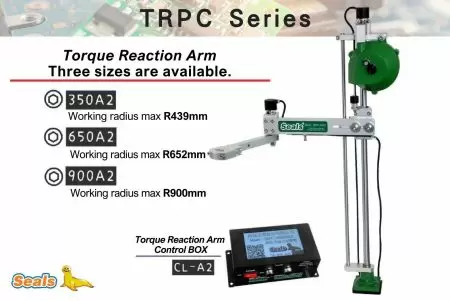

Torque Linear Arm ( 298mm horizontal Stroke)

TA-300

Seals TA-300 Torque Linear Arm provide a 300mm linear motion working radius. With high ranking fine finished steel rod and linear motion ball bearing, TA-300 provides load free experience in horizontal action. Meanwhile, it also have a standard vertical 218mm stroke distance.

Torque Linear Arm ( 594mm horizontal Stroke)

TA-600

Seals Torque Reaction Arm designed to avoid for injuries caused by repetitive work and overusing the arm can occur in daily work activities. We provide the opportunity to implement ergonomic improvements to the manufacturing process. This torque reaction arm removes torque twisting and weight loading to create a safe work environment.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.