Automatic Screw horizontal seat-TA series torque reaction arm

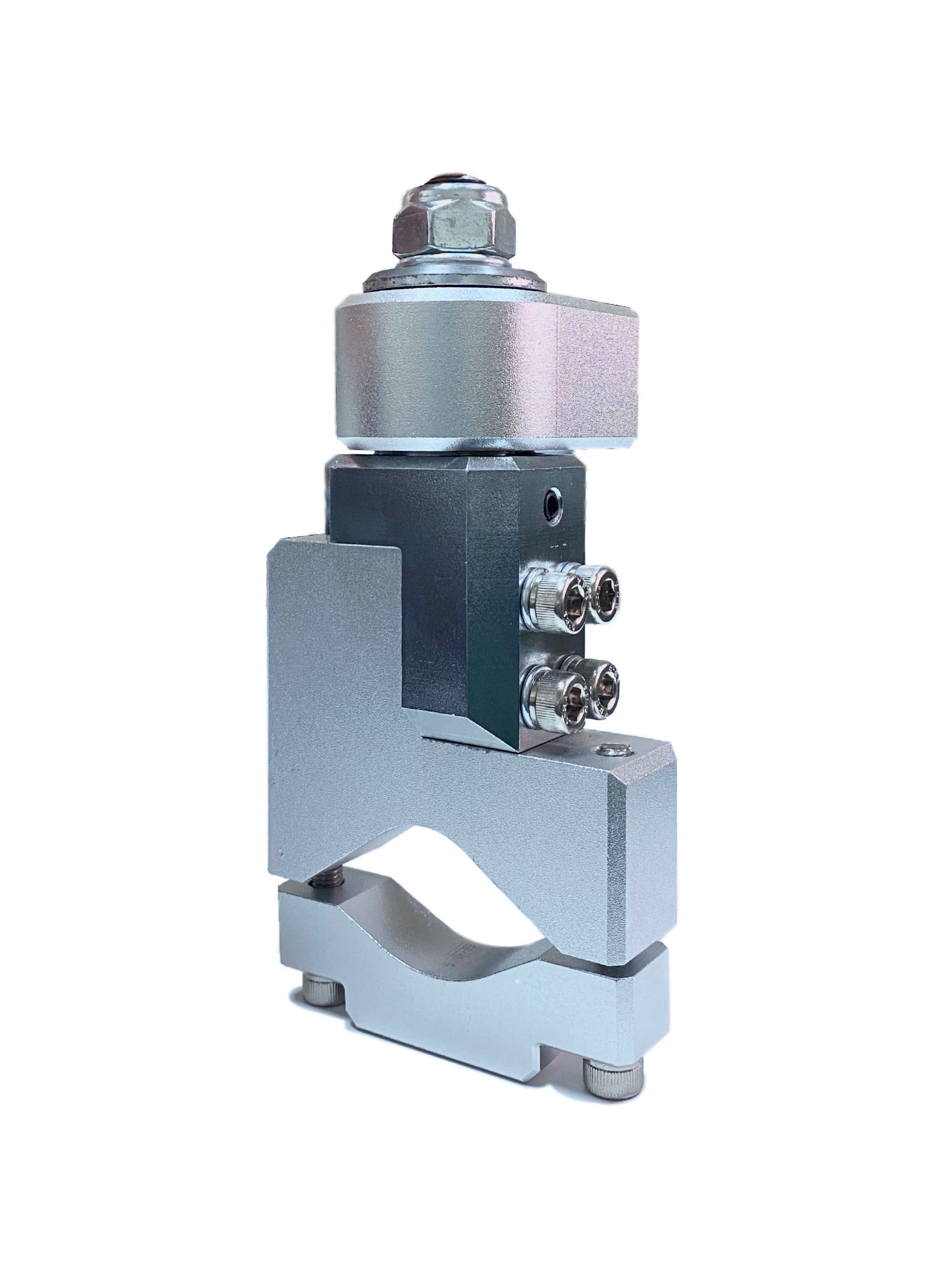

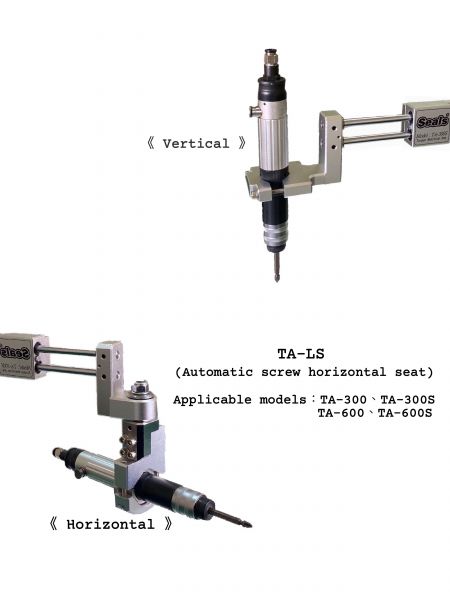

TA-LS

The Automatic screw horizontal seal is optional and can be easily installed on the Torque Reaction Arm with a hexagonal wrench for horizontal operation.

In accordance with the requirements of the production line in the factory, vertical operations can be carried out. After installing the Automatic screw horizontal seal, horizontal operations can be operated, which increases the diversification of operations.

Automatic Screw horizontal clamping seat TAL series applicable torsion arm support models: TA-300, TA-300S, TA-600, TA-600S

Nickname

Screwdriver horizontal fixing seat, horizontal clamping seat, Screwdriver horizontal clamping seat

Features

1. Increase the operating methods that can be performed on the Torque Supporting Arm support.

2. Use hexagonal wrench, simple installation and disassembly.

3. It can also quickly change horizontal and vertical operations according to the requirements of the production line.

Applications

- Screwdriving.

- Drilling and Tapping.

- Automatic Screw Feeding.

- Impact Wrenches.

- Impact Tools.

- Pulse Tools.

- Gallerys

- Related Products

Torque Linear Arm ( 298mm horizontal Stroke)

TA-300

Seals TA-300 Torque Linear Arm provide a 300mm linear motion working radius. With high ranking fine finished steel rod and linear motion ball bearing, TA-300 provides load free experience in horizontal action. Meanwhile, it also have a standard vertical 218mm stroke distance.

Torque Linear Arm ( 594mm horizontal Stroke)

TA-600

Seals Torque Reaction Arm designed to avoid for injuries caused by repetitive work and overusing the arm can occur in daily work activities. We provide the opportunity to implement ergonomic improvements to the manufacturing process. This torque reaction arm removes torque twisting and weight loading to create a safe work environment.

Torque Linear Arm ( 182-561mm working radius)

TA-300S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loadsAfter clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1122mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws.This Torque Reaction Arm can effectively reduce the space requirement of the workplace.With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment.It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

Torque Linear Arm ( 236-744mm working radius)

TA-600S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loadsAfter clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1488mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws.This Torque Reaction Arm can effectively reduce the space requirement of the workplace.With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment.It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

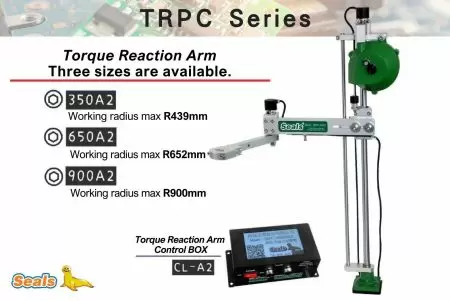

Automatic Screw horizontal seat-TR series torque reaction arm

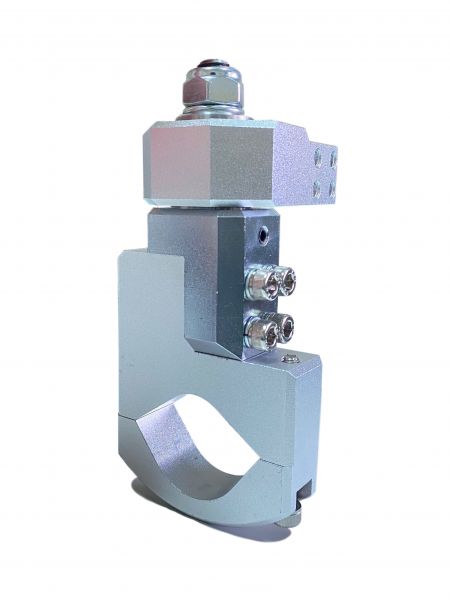

TR-LS

The Automatic screw horizontal seal is optional and can be easily installed on the Torque Reaction Arm with a hexagonal wrench for horizontal operation.In accordance with the requirements of the production line in the factory, vertical operations can be carried out. After installing the Automatic screw horizontal seal, horizontal operations can be operated, which increases the diversification of operations.Automatic Screw horizontal clamping seat TRL series applicable torsion arm support models:TR-350、TR-650

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.