Single Axis Automatic Screw Feeding

CM-100

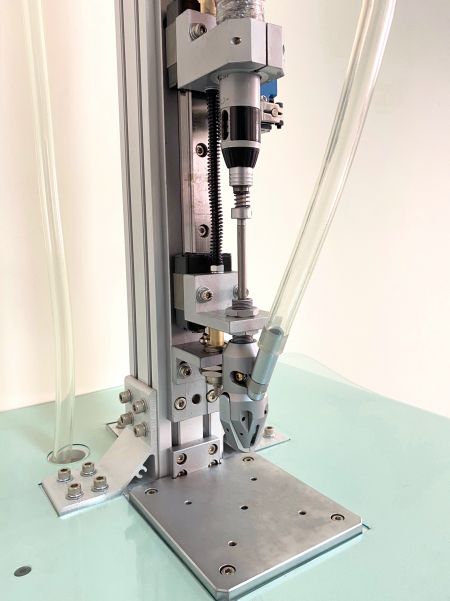

CM-100 Single axis automatic screw feeding, The operator only need to pick and load the Workpiece, lightly step on the foot switch, the screwdriver will automatically complete the screw locking.

After transferring the CM-100L to the screw hole, the screw will be ejected, tightened, re-feeding, and signal returned in 1.0~2.0 seconds. (Depending on the screw thread length, tooth pitch, electric screwdriver speed, self-power... and other factors, the calculation time of the case) the accuracy of screw locking and the tightening torque are all completed by the machine, which increases quality stability and improves production effectiveness.

It can be quickly conform into an automated production line, can be easily installed in a work station, and can control a single cylinder.

Features

1.Automatic feeding to completely save the screw picking and moving action.

2.The pneumatic torque-controlled screwdriver is used to improve the fastening quality for the customer.

3.Fiber Optic control intellectual-type feeding,saving power while avoiding short supply.

4.The bit push the screw for fastening automatically,

It prevents the jaw from contacting the surface of the work-piece;thus it will neither rub the product nor produce too much stress.

5.Equipped with aluminum extrusion, excellent verticality, easy and fast height adjustment.

6.Foot switch, easy to operate.

7.Equipped with a simple electric control box, economical.

8.The personnel only need to take and place the workpiece, and the screw can be locked without time and effort.

Function

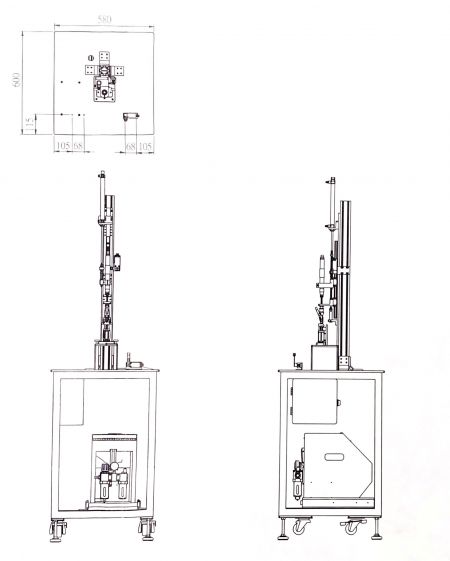

《30F》Specification

《30F》Specification 《501F》Specification

Voltage:220V、Single Phase Voltage:220V、Single Phase

Air Pressure:5.5 kg / cm² / 85PSI Air Pressure:5.5 kg / cm² / 85PSI

L / W / H:35 / 25 / 38 cm L / W / H:35 / 25 / 38 cm

Capacity:30 pcs/min. Capacity:50 pcs/min.

——Choose Feeder according to your needs——

- Gallerys

- Related Products

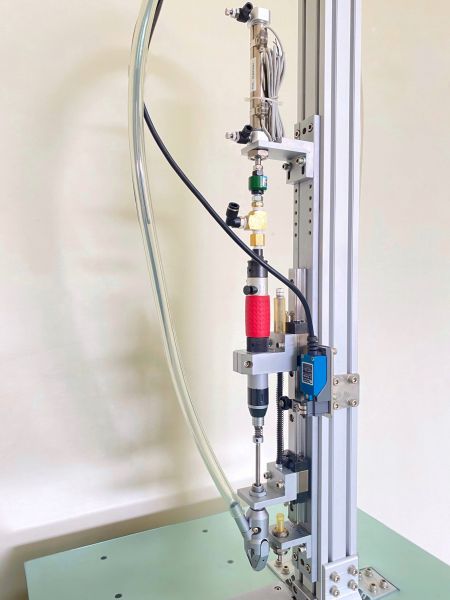

Spindle Type Automatic Screw Feeding Module by one cylinder

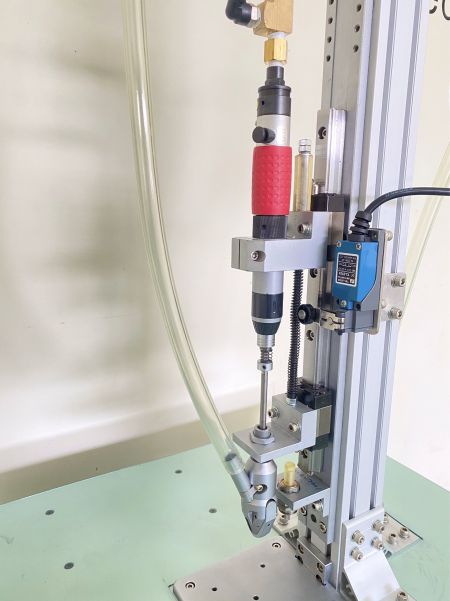

CM-100L

SEALS CM-100L is a basic spindle type screw feeding module for fully automation purpose. Comparing with CM-100S, CM-100G, the one cylinder structure is outstanding in the cost and its narrow pictch requirement. You only need to integrate this module into screw fasten position. SEALS CM-100L provides basic cylinder stroke control and adopts push-start torque control pneumatic screwdriver. Most of all, by its compact design in width, it could install side by side with min. 45mm pitch screw hole application. Meanwhile, CM-100L performs durability, reliability and precision for your best screw assembly components option in automation.p

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Vibration Bowl Type Automatic Screw Feeder

CM-501

SEALS CM-501 Vibration bowl type automatic screw feeder could speed up to 50 pieces per minute. And, it could design for screw from M1.0 to M8 and screw length up to 30 mm. It is easy to maintenance due to its simple structure. Due to the tank, it could load more screw than sword type automatic screw feeder.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.