-

Air Nipper ( 60kg pressing power)

YM-60

The SEALS YM-60 is a handheld air nipper with a 36 mm grip diameter and a weight of 189 g, offering a compact and easy-to-hold design suitable for various industrial cutting applications. It can be equipped with the optional S4 standard blade, designed for cutting up to 1.6 mm copper wire and 1.0 mm iron wire. The blade is made from specially treated steel, engineered for cutting molybdenum wire, iron wire, copper terminals, plastic injection products, resin, closed-end terminals, bare terminals, power cord clips, copper tubes, fabrics, European-style terminals, plastic leather, clamps, and more. SEALS offers 11 major blade series and 43 standard specifications to meet a wide range of needs. The body is made from high-quality aluminum alloy for durability and portability, featuring an adjustable airflow valve for precise power control. Quick-change blade design minimizes downtime, making it ideal for high-frequency, repetitive cutting operations, reducing operator fatigue, improving ergonomics, and enhancing productivity. (Suitable for 1.6mm iron wire / 1.0mm iron wire)

-

Air Nipper / Air Terminal Crimper ( 140kg pressing power)

YM-140

SEALS blades are made from specially treated steel, designed for various applications such as cutting molybdenum wire, iron wire, copper terminals, plastic injection parts, resin, closed-end terminals, bare terminals, power cable clamps, copper tubes, fabric, European terminals, synthetic leather, and hose clamps. Eleven major blade series with forty-three standard specifications are available, offering a wide range of choices. The SEALS YM-140 features a 45 mm diameter aluminum die-cast body that is lightweight, durable, and easy to handle. Equipped with an integrated airflow adjustment valve, it allows precise control of output power to meet specific operational needs. It can be paired with optional blades from SEALS, suitable for cutting metal wires, trimming PCB leads, crimping terminals, and pressing adhesive materials. The quick-change blade design ensures easy replacement and maintenance. A variety of body sizes and blade specifications are available to meet different production line cutting and crimping requirements. (Suitable for cutting wire-S5 blade, shearing resin-FD-6 blade, crimping wire buckle-CLP blade, pressing bare terminal-A5P blade and pressing insulated terminal-AR5P blade)

-

Air Nipper / Air Terminal Crimper ( 208kg pressing power)

YM-280

The SEALS YM-280 features an aluminum die-casting body with a 45 mm diameter and an extended body design. This extended body enhances cutting and crimping power without increasing the grip diameter, ensuring a more comfortable holding experience. Equipped with a variety of optional blades from SEALS, it can be applied in crimping various specifications of insulated and non-insulated terminals, as well as cutting molybdenum wires, iron wires, copper heads, plastic injection parts, resin, closed-end terminals, bare terminals, power cord bushings, copper tubes, fabrics, European terminals, plastic leather, hose clamps, and more. The aluminum body is lightweight yet durable, with an integrated air volume adjuster for precise power control according to operational needs. The blade replacement process is quick and easy, ensuring simple maintenance. The SEALS YM series handheld air nipper helps reduce operator fatigue, provides ergonomic handling, and boosts productivity. It is especially ideal for repetitive crimping, cutting, squeezing, and pressing applications, all operated with a simple lever trigger. SEALS offers a wide range of air nipper models and blade options to meet diverse industrial requirements, with an optional rotatable body available for both right- and left-handed operators. (Suitable for pressing bare terminal - A7P1 blade and insulated terminal - AR7P1 blade)

-

Air Nipper / Air Terminal Crimper ( 280kg pressing power)

YM-300

The YM-300 features a robust 56 mm diameter aluminum die-cast body, delivering higher structural rigidity and stability for medium-to-heavy duty cutting and crimping operations. Compatible with SEALS’ specialized blades, it supports a wide range of tasks including wire cutting, PCB lead trimming, terminal crimping, and glue material pressing. Blades are manufactured from specially treated steel, ensuring exceptional durability and performance across different materials such as molybdenum wire, iron wire, copper terminals, plastic injection parts, resin, copper tubes, fabrics, and synthetic leather. With 11 major series and 43 standard blade models available, there’s a solution for virtually every production requirement. The integrated air volume adjuster allows fine control over output force, while the quick-change blade system ensures minimal downtime during maintenance. The rotatable body design accommodates both right- and left-handed operators, reducing fatigue and improving productivity in repetitive cutting, crimping, and pressing tasks. (Suitable for cutting wire-S8P blade, shearing resin-FD-8P blade, crimping wire buckle-CLP blade, pressing bare terminal-A7P blade and pressing insulated terminal AR7P blade)

-

Air Nipper / Air Terminal Crimper ( 450kg pressing power)

YM-480

The SEALS YM-480 features an aluminum die-cast body with a 56 mm diameter and an extended body design, delivering greater cutting and crimping power without increasing the tool’s diameter for a more comfortable grip. When paired with a wide range of SEALS specialized blades, it can be applied to cutting metal wires, trimming PCB leads, crimping terminals, and pressing glue-containing materials. The blades are made from specially treated steel, making them suitable for a variety of workpieces such as molybdenum wire, iron wire, copper heads, plastic injection parts, resin, closed terminals, bare terminals, power cord clips, copper tubes, fabrics, European terminals, plastic leather, hose clamps, and more. SEALS offers eleven major blade series and forty-three standard specifications to meet diverse application needs. The built-in air volume adjuster allows precise control of output force according to operational requirements, while the quick-change blade design ensures easy replacement and simple maintenance. The SEALS YM series handheld air nippers help reduce operator fatigue, provide ergonomic handling, and increase productivity. They are ideal for repetitive crimping, cutting, squeezing, and pressing tasks, all accomplished with a simple lever trigger. A wide variety of body sizes and blade options are available, with rotatable bodies designed for both right- and left-handed operators. (Suitable for cutting wire-S8P blade, shearing resin-FD-8P blade, crimping wire buckle-CLP blade, pressing bare terminal-A7P blade and pressing insulated terminal AR7P blade)

-

Air Terminal Crimper ( 650kg pressing power)

YM-600

The YM-600 features a 56 mm diameter aluminum die-cast body with an extending design, delivering enhanced cutting and crimping power without increasing the tool diameter, resulting in a more comfortable grip. Equipped with versatile SEALS blades, it is suitable for cutting wires, trimming PCB leads, crimping terminals, and pressing glued materials. The specially treated steel blades from SEALS are designed for a wide range of workpieces including molybdenum wire, iron wire, copper heads, plastic injection parts, resin, closed and non-insulated terminals, power cable clips, copper tubes, fabric, European terminals, plastic leather, and hose clamps. With eleven blade series and forty-three standard specifications, SEALS offers a variety of options to meet diverse applications. The lightweight aluminum body is easy to handle, and the built-in air volume adjuster allows precise control of operating force. Blade replacement is quick and simple for minimal downtime. The SEALS YM series handheld air nippers help reduce operator fatigue and enable ergonomic, high-productivity operation. Ideal for repetitive crimping, cutting, squeezing, and pressing tasks, these jobs can be completed with just a light lever trigger. A wide range of air nippers and blades are available for different industrial requirements, and the rotatable tool body accommodates both right-handed and left-handed operators. (Suitable for pressing bare terminal-A12WP blade and crimping insulated terminal AR12WP blade)

-

Air Nipper / Air Terminal Crimper ( 280kg pressing power)

AM-300

The SEALS AM-300 automation Air Nipper / Air Terminal Crimper can be seamlessly integrated into fully automated robots or machinery and controlled via an electromagnetic valve. It features a precision-machined aluminum body with a 56mm diameter, maintaining the lightweight yet durable characteristics of the SEALS series. When equipped with SEALS’ durable, application-specific blades, it delivers high productivity and operational efficiency for repetitive crimping, cutting, squeezing, and pressing tasks. The blades are made from specially treated steel, suitable for molybdenum wire, iron wire, copper terminals, plastic injection parts, resin, closed-end terminals, non-insulated terminals, strain relief bushings, copper tubes, woven fabrics, European terminals, plastic leather, and clamps. The SEALS blade range covers eleven main categories with forty-three standard specifications, offering versatile solutions for various industrial needs. The tool body is equipped with an airflow adjuster to fine-tune the operation power as required. Blade replacement is quick and simple, ensuring minimal downtime. A range of optional accessories—such as tool body fixtures, foot pedals, and foot pedals with safety covers—are also available to meet different operational setups. (Suitable for cutting wire-S8P blade, shearing resin-FD-8P blade, crimping wire buckle-CLP blade, pressing bare terminal-A7P blade and pressing insulated terminal AR7P blade)

-

Air Nipper for cutting wire

S series

The SEALS S Series Power Cutting Blades are specially designed for cutting copper wire, iron wire, and various industrial materials such as plastic parts, resin, connectors, wire locks, copper tubes, textile, European terminals, synthetic leather, and clamps. With six sub-series and thirty standard models, SEALS offers a wide selection of cutting capacities to meet different industrial requirements. The nipper body is made of lightweight aluminum alloy, providing both durability and convenience. An adjustable air flow valve is applied to regulate the operation power according to different working needs. The blade replacement process is quick and simple, allowing users to reduce downtime and achieve higher productivity. (Designed for Metal Wire Applications)

-

Air Terminal Crimping Plier for insulated terminal

A series

The SEALS A Series Air Terminal Crimping Nippers are specifically designed for non-insulated terminal crimping applications. Several models are available to accommodate different wire gauges, such as 1.25sq, 2.0sq, 5.5sq, 8.0sq, and 14.0sq. The A Series is compatible with multiple tool bodies including YM-140, YM-140L, YM-280, YM-300, YM-480, YM-500, YM-600, AM-140, and AM-300, offering a wide range of operational flexibility. SEALS blades are made of specially treated steel to ensure durability and precision. They are designed for various applications, including molybdenum wire, iron wire, copper terminals, plastic injection, resin, closed terminals, non-insulated terminals, wire lockers, copper tubes, fabric, European terminals, plastic leather, and clamps. Across the full range, SEALS offers 11 blade series with 43 standard specifications, providing a comprehensive selection for diverse needs. The tool body is made of lightweight aluminum alloy, equipped with an air volume regulator to adjust operation power as required. Quick and simple blade replacement ensures easy maintenance and enhances productivity. (Applicable to Non-Insulated Terminal Crimping Blades)

-

Air Crimper for Brake Wire End Cap / Cable End Cap

A5P

SEALS A5P series air crimping pliers are specially designed for crimping brake wire end caps and cable end caps, with a crimping capacity of 1.25sq. Made of heat-treated alloy steel, the blades deliver high precision, durability, and reliable performance without jamming. They are compatible with SEALS tool bodies such as YM-140, YM-140L, and AM-140, providing a compact, lightweight, and efficient crimping solution. The quick blade replacement mechanism and adjustable air flow control valve allow operators to fine-tune the crimping force for different applications. SEALS blade series covers 11 categories with 43 standard models, offering a wide range of options for diverse industrial needs. (Applicable to crimping blades for brake wire end caps)

-

Air Plier for strain relief bushing clamping

CLP series

SEALS Strain Relief Bushing Crimping Blade Plier, CLP series, is designed for clamping and securing strain relief bushings with diameters ranging from 10mm to 22mm. This series provides several blade options to ensure reliable and precise crimping results. They are suitable for tool bodies YM-140, YM-140L, YM-280, YM-300, YM-480, YM-500, YM-600, AM-140, and AM-300. Manufactured with specially treated high-grade steel, SEALS blades deliver durability and long service life, ensuring consistent performance when working with various materials, such as molybdenum wire, iron wire, copper heads, resin, injection-molded parts, closed terminals, non-insulated terminals, strain relief bushings, copper tubes, fabrics, European-style terminals, plastic leather, and clamps. The lightweight aluminum tool body is equipped with an adjustable airflow valve, allowing operators to easily fine-tune the clamping force to meet specific application requirements. Blades can be replaced quickly and conveniently, minimizing downtime and improving production efficiency. (Suitable for crimping blades for strain relief bushing terminals)

-

Air Plier for copper pipe clamping

Y-2

The SEALS Y-2 copper tube crimping plier is specially designed for the refrigerator and air-conditioning industry. Two tool body options are available: ◎AM-300 with reverse trigger lever design: The crimping action is activated when the lever is released, and the blade opens when the lever is pressed. This allows the tool to crimp the material and hold it in place without continuous handheld operation, enabling the operator to proceed with sealing tasks conveniently. ◎AM-300 with hand slide valve: This option also enables the tool to clamp the tube and hold it steadily, leaving both of the operator’s hands free for sealing or assembly work. The Y-2 series is equipped with a volume adjuster to regulate the clamping power. In addition, a setting screw allows adjustment of a specific clamping gap for precise control. All SEALS blades are made from specially treated steel and are designed for a wide range of applications, including molybdenum wire, iron wire, copper heads, plastic injection parts, resin, closed-end terminals, bare terminals, strain relief bushings, copper tubes, fabrics, European terminals, plastic leather, clamps, and more. The product line covers 11 series with 43 standard specifications, offering versatile options for different requirements. SEALS blades are quick and easy to replace, while the lightweight aluminum tool body ensures portability, durability, and improved working efficiency.

-

Air Plier for flat pressing

FP-1

SEALS FP series flat pressing blades are made of specially treated steel and designed for various applications, such as molybdenum wire, iron wire, copper heads, resin, closed-end terminals, bare terminals, strain relief bushings, copper tubes, fabrics, European terminals, plastic leather, clamps, and more. With 11 series and 43 standard specifications, SEALS offers a wide range of choices. The FP series is compatible with YM-140, YM-140L, YM-280, YM-300, YM-480, AM-140, and AM-300 tool bodies. The aluminum body provides lightweight and convenient operation, with an adjustable air valve to control pressing power as required. Blade replacement is quick and easy, ensuring efficient operation and simple maintenance.

-

Air crimping Plier for oeatik pex ring

PC Type

SEALS PC series professional crimping blades are specially designed for one-ear PEX ring clamps. The series includes two models, PC-2 and PC-4, to meet different ear widths and clamping force requirements. All SEALS blades are manufactured from specially treated steel, ensuring durability and precision. They are suitable for a wide variety of applications, including molybdenum wire, iron wire, copper heads, plastic injection parts, resin, closed-end terminals, non-insulated terminals, strain relief bushings, copper tubes, fabrics, European-style terminals, synthetic leather, and one-ear clamps. The SEALS blade system is divided into 11 major series with 43 standard specifications, offering a broad selection for diverse applications. The blades are quick and easy to replace, while the lightweight aluminum tool body with an air flow regulator allows operators to adjust the crimping force as required. Compatible Tool Bodies: YM-300, YM-480, AM-300

-

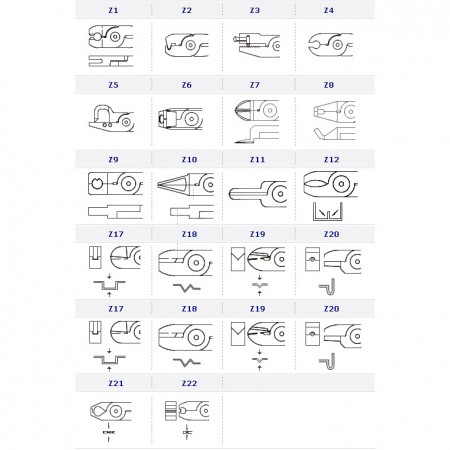

Customized Air Terminal Crimper

SEALS provides customized blade solutions to meet diverse crimping requirements for different terminals and workpieces. Applications cover molybdenum wire, iron wire, copper tubes, closed-end terminals, non-insulated terminals, plastic molded parts, leather, fabric, clamps, and other special-shaped terminals. The Z series offers more than 20 variations (e.g., Z1–Z22), including cutting, flattening, diagonal trimming, and special terminal crimping. All SEALS blades are made of specially treated steel for durability and long service life. They can be easily replaced and are compatible with lightweight aluminum tool bodies equipped with an adjustable air flow regulator, allowing operators to fine-tune the crimping force for specific needs. Application Examples: ● Customized terminal crimping ● Flattening or cutting special-shaped metal parts ● Non-standard component fastening and processing

- Home Homepage

- Company Company Profile

- Products Product Category

-

Application Summary

- CM-300→Three-Axis Automatic Pin Insertion Machine – Woodworking Application

- CM-30→Refrigerator & Appliance Assembly Application

- TRPC-A3→Low-error assembly processes

- CM-200→Eyeglass Hinge Screw Fastening

- CM-500→Gas Meter Top & Bottom Cover

- SB/HSB Series→Line Organization and Labor-Saving Applications

- TAB/THB Series→Hose Management & Air Supply Integration

- CM-A1~A4→Automatic Nipple Feeder – Bicycle Rim Assembly Line

- CM-200→Compressor Connecting Rod Nut Tightening Application

-

Q&A Knowledge Hub

- Definition of Tool Torque

- Choose power cord buckle pliers

- Daily Maintenance and Care Recommendations for automatic screw feeder

- Advantages of Using an Automatic Screw feeder

- Purpose of a Torque Reaction Arm

- Seals Automatic Screw Feeder Types

- Customer Inquiry and Ordering Process Guide

- Screw Locking Solutions for Deep and Special Screw Positions

- Application Scope of Automatic Screw Locking Machines

- Smart Screwdriving for Enhanced Production Efficiency

- Air Cutter / Terminal Crimping Tool: Body Section

- Air Cutter / Terminal Crimping Tool: Blade Section

- Spring & Hose Balancers FAQ

- Efficiency Comparison Between Automatic Screw Feeder and Manual Fastening: An Investment Analysis for Production Automation

- E-CATALOG Download Collection

-

News Event and News

- Holiday Closure Notice

- Taichung Industrial Automation Exhibition 2025

- 2025 Taipei Cycle Show

- Lunar New Year Holidays Notice

- Compant Trip Notify

- Holiday Closure Notice

- 2024 Taipei Cycle Show

- 2023 Taipei Cycle Show

- 2022 Toyo×Education Training

- 2022 Taipei AMPA

- 2022 Taipei Cycle Show

- 2022 Education and Training Course《Accountability》

- *Postpone* 2021 Taipei Cycle Show

- 2021 Toyo×Education Training

- *Notice* 2021 Taipei Cycle Show

- 2019 Taipei International Cycle Show

- 2018 72nd Industrial Festival and Innovation and R&D Excellent SMEs

- 2018 Taipei International Cycle Show

- 2018 Achieves ISO Certification for Quality Management

- 2016 Winning Taichung Golden Hand Award

- 2016 Taipei International Cycle Show

- 2015 Taiwan Hardware Show

- 2015 Taipei International Cycle Show

- 2014 Taiwan Hardware Show

- 2014 Taipei International Cycle Show

- 2013 Auto Shanghai

- 2013 Taipei Int'l Auto Parts & Accessories Show

- 2013 Taipei Int'l Cycle Show

- 2012 Taipei Int'l Auto Parts & Accessories Show

- 2012 Taiwan Int'l Lighting Show

- 2012 Taipei Int'l Cycle Show

- 2011 TPCA Show, Taipei

- 2011 Taichung Industrial Automation Exhibition

- 2011 Taipei International Industrial Automation Exhibition

- 2011 New Taipei City Industrial Automation Exhibition

- 2011 Kaoshung Industrial Automation Exhibition

- 2011 Taipei International Cycle Show

- 2011 The Indonesia International Bike, parts & Accessories Exhibition

- 2010 TPCA Show, Taipei

- 2010 EPCON South China / ATE China

- 2010 Vietnam Auto & Petrol

- 2010 Taipei International Cycle Show

- 2007 Taipei International Industrial Automation Exhibition

- 2007 Taipei International Cycle Show

- 2005 Practical World, Koln

- 2004 Practical World, Koln

- Contact Us Contact Info.