YM-30 + OTHERS → Medical Application Air Nipper

《Case Description》

A Critical Tool for Ultra-Fine Wire Insertion

— Application of the Customized YM-30 Air Holding Nipper in Implantable Electronic Medical Devices

As implantable electronic medical devices continue to evolve toward miniaturization, higher density, and increased precision, the dimensions of wires and terminals used in neural stimulators, sensing electrodes, and related electronic modules have been reduced to levels that are difficult to handle using conventional electronic assembly methods.

In such advanced medical manufacturing processes, the ability to stably handle ultra-fine wires at hair-scale diameters, while ensuring assembly consistency and reliability, has become a critical factor affecting overall product quality.

【Practical Manufacturing Challenges in Implantable Electronic Medical Devices】

During the manufacturing of implantable electronic medical devices, ultra-fine wires must often be precisely inserted into micro-sized metallic tubular terminals before subsequent fixation or encapsulation processes.

In this application, the corresponding terminal specifications are as follows:

◎Tubular metal terminal

◎Outer diameter: approximately Ø0.26 mm

◎Length: approximately 1.5 mm

The wires themselves are only about 1–2 strands of hair in diameter, soft in texture and prone to uncontrolled movement. Combined with the extremely small size of the tubular terminals, wire insertion must be performed under a microscope.

When relying solely on fingers or general-purpose tools, the wires are highly susceptible to bending, slipping, or misalignment, resulting in unstable processes and potential material damage.

【Why a Dedicated Wire Holding and Guiding Tool Is Required】

In such manufacturing scenarios, the primary purpose of the tool is not to cut the wire, but to:

◎Stably hold ultra-fine wires

◎Control wire direction and insertion angle

◎Assist smooth and accurate insertion into micro tubular terminals

◎Reduce heavy dependence on operator experience and manual skill

Without dedicated tooling support, it is difficult to maintain a high success rate and consistent quality in wire insertion processes, making stable production and scalability challenging.

Application of the Customized YM-30 Air Nipper

In this application case, the SEALS YM-30 Air Nipper Body is selected as the base mechanism.

Based on specific process requirements, the tool is further adapted through a customized Air Nipper Blade design, transforming it from a cutting tool into a dedicated pneumatic micro holding nipper for ultra-fine wire handling.

The key application features include:

Customized Air Nipper Blade Geometry

The Air Nipper Blade is not designed for cutting purposes. Instead, it forms a stable and gentle holding surface, preventing scratching, deformation, or flattening of ultra-fine wires during operation.Consistent and Controllable Holding Stroke

Pneumatic actuation ensures consistent gripping force and stroke for each operation, minimizing variations caused by manual force and improving overall process repeatability.Stable Wire Direction Control

During the wire insertion process, the tool securely holds and guides the wire, enabling accurate insertion into Ø0.26 mm micro tubular terminals.Compact Design for Microscope-Assisted Operation

The miniaturized Air Nipper Body allows flexible operation under high-magnification microscopes, meeting the spatial and precision requirements of medical manufacturing processes.

Benefits for Medical Manufacturing

By adopting this customized pneumatic holding solution, implantable medical electronic manufacturing processes can achieve clear and measurable improvements:

Enhanced success rate and consistency in ultra-fine wire insertion

Reduced risk of wire bending, surface damage, and material scrap

Lower dependency on highly experienced manual operators

Improved process stability, supporting repeatable production

Compliance with the stringent quality and reliability requirements of high-end medical electronics

These advantages are particularly critical for the mass production and quality control of implantable medical devices and related electronic modules.

Precision Tools Supporting Advanced Medical Applications

As wire diameters shrink to hair-scale dimensions and terminal structures fall below millimeter-level sizes, the manufacturing process itself becomes a highly specialized technical challenge.

Through customized designs based on the YM-30 Air Nipper Body, SEALS provides precision pneumatic holding tools tailored to medical manufacturing requirements, enabling stable and reliable ultra-fine wire insertion and serving as a key auxiliary solution in the production of advanced implantable electronic medical devices.

Seals Core Technologies & Practical Value

- Dedicated holding geometry for ultra-fine wires

- Pneumatic actuation with consistent holding stroke

- Stable wire direction control for precise insertion

- Compact design suitable for microscope-assisted operation

- Reduced dependence on highly skilled manual handling

- Related Products

Air Nipper ( 27kg pressing power)

YM-30

SEALS YM-30 hand held air nipper has a 20mm diameter body. Its mini size body is very easy to hold and to reach a narrow space. It adopts S20 wire cutter (optional). The sharp shape of S20 is very useful for cutting legs of IC board. It use special treatment material to cut copper wire and iron wire.SEALS YM series handheld air nipper can help reducing operator fatigue and achieving ergonomic operation and higher productivity. Especially for repetitive crimping, cutting, squeezing, pressing applications, these jobs will be done by just a easy lever trigger. SEALS Air Nipper provides wide range options of air nippers and blades for variety industrial demand. Rotatable SEALS air nipper tool body is available for right hand and left hand operator.(Suitable for 0.8mm iron wire / 0.5mm iron wire)

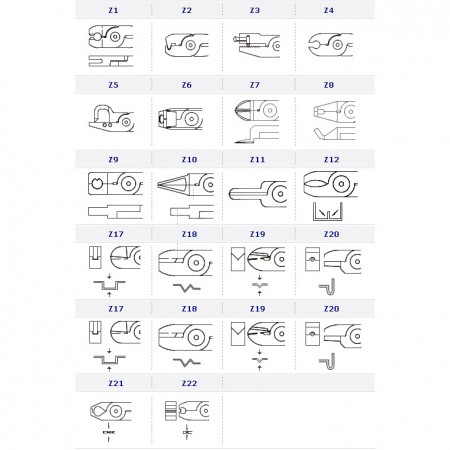

Customized Air Terminal Crimper

SEALS provides customized blade solutions to meet diverse crimping requirements for different terminals and workpieces. Applications cover molybdenum wire, iron wire, copper tubes, closed-end terminals, non-insulated terminals, plastic molded parts, leather, fabric, clamps, and other special-shaped terminals.The Z series offers more than 20 variations (e.g., Z1–Z22), including cutting, flattening, diagonal trimming, and special terminal crimping. All SEALS blades are made of specially treated steel for durability and long service life. They can be easily replaced and are compatible with lightweight aluminum tool bodies equipped with an adjustable air flow regulator, allowing operators to fine-tune the crimping force for specific needs.Application Examples: ● Customized terminal crimping ● Flattening or cutting special-shaped metal parts ● Non-standard component fastening and processing