Efficiency Comparison Between Automatic Screw Feeder and Manual Fastening: An Investment Analysis for Production Automation

(1) Introduction – The Rationale for Comparison

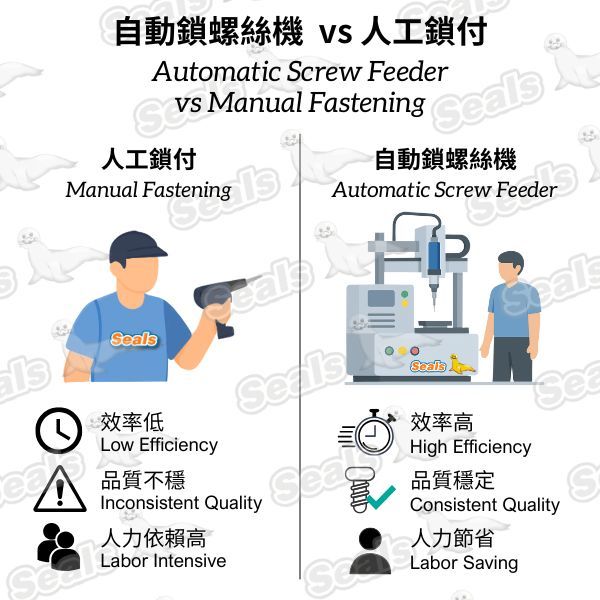

In manufacturing production lines, manual screw fastening is still a common method. However, as product precision and production demands increase, manual operations are gradually reaching their limits. So, how does an Automatic Screw Feeder truly compare with manual fastening?

(2)Efficiency Comparison

▶︎ Manual fastening: Depending on operator skill, each screw typically requires 3–5 seconds. Efficiency decreases with prolonged operation due to fatigue.

▶︎ Automatic Screw Feeder: With automatic screw feeding and torque control, each screw can be fastened within 1–1.5 seconds. A single operator can manage multiple units, improving efficiency by 2–3 times or more.

(3)Quality and Consistency

▶︎ Manual fastening often results in inconsistent depth, stripped threads, or missing screws.

▶︎ Automatic Screw Feeders are equipped with torque setting and detection functions, ensuring consistent fastening quality and reducing the risk of defects.

(4)Labor and Cost

▶︎ Manual fastening relies heavily on labor and often leads to wrist strain and injuries. With rising labor costs, it is not sustainable in the long run.

▶︎ Automatic Screw Feeders allow one operator to manage multiple machines, reducing labor dependency. ROI can typically be achieved within 6–12 months, depending on production volume.

(5)Use Cases and Applications

▶︎ Manual fastening: Suitable for small-batch production, frequent product changes, or prototype development.

▶︎ Automatic Screw Feeder: Best suited for high-volume, long-term production in industries such as electronics, automotive components, and medical devices.

(6)Comparison Table

| Criteria | Manual Fastening | Automatic Screw Feeder |

| Efficiency | 3–5 sec/screw | 1–1.5 sec/screw, 2–3× faster |

| Consistency | Highly dependent on operator | Torque-controlled, stable fastening quality |

| Labor Requirement | Multiple operators needed | One operator can manage multiple machines |

| Safety & Fatigue | High risk of strain and injuries | Reduces strain, improves workplace safety |

| Cost Effectiveness | Lower short-term cost | Saves labor and defect costs in the long term |

(7)Conclusion & Call to Action (CTA)

In conclusion, Automatic Screw Feeders clearly outperform manual fastening in efficiency, quality stability, and labor cost reduction. For manufacturers aiming for higher productivity and standardized processes, they represent a valuable automation investment.

👉 Learn more about our models and applications:

📊Download Catalog 👉[Download the Full Product Catalog]

📩Contact Us 👉[Get in Touch with Us Today]

- Related Products

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Automatic Screw Feeder with Lever-Activating Design

CM-40T

The SEALS CM-40T Automatic Screw Feeder is designed based on the principles of speed, stability, and convenience. It integrates pneumatic or electric torque-controlled screwdrivers, precision-engineered jaws, and a reliable horizontal feeding mechanism to significantly improve fastening speed and overall production efficiency.The system features an ergonomic lever-activated design that allows the operator to simply press the lever, prompting the screwdriver bit to automatically push downward and complete the fastening process. This design minimizes the required press stroke, reduces operator fatigue, and enhances productivity. The jaw is engineered to avoid direct pressure on the surface of the workpiece, effectively protecting product finishes and coatings from damage.To meet the demands of automated manufacturing, the CM-40T can also be integrated into various automation platforms such as XY tables, SCARA robots, 6-axis robotic arms, or other custom automatic assembly systems. The automation-ready version supports input/output signal communication and can seamlessly interface with major control systems.

Vibration Bowl Type Automatic Screw Feeder

CM-501

The SEALS CM-501 vibration bowl type automatic screw feeder is designed for speed, stability, and convenience. With a maximum feeding rate of 50 screws per minute, it significantly improves fastening efficiency in production environments.The system supports a wide range of screw sizes, from M1.0 to M8, and screw lengths up to 30 mm. Compared to sword-type feeders, the vibration bowl design provides a larger screw capacity due to its built-in tank, making it suitable for long-duration operations with fewer refills.Integrated with a pneumatic or electric torque-controlled screwdriver and a custom precision jig, the CM-501 offers stable, reliable fastening performance across various applications such as electronics, aluminum products, plastic components, and hardware assemblies.Its simplified mechanical structure allows for easier maintenance and long-term operational stability. The jig and feeding configuration can also be customized to match specific screw dimensions and workpiece requirements.

VGA, DVI Card Automatic Screw Feeder

CM-B1

The SEALS CM-B1 Automatic Screw Feeder is specially designed for fastening hexagonal standoff screws onto VGA, DVI, and other computer interface cards. Built for speed, stability, and convenience, the system integrates precision-engineered jaws, a high-efficiency feeding unit, and pneumatic/electric torque-controlled screwdrivers to ensure fast, accurate, and consistent fastening.Equipped with an auto bit-pushing function, the CM-B1 supports horizontal screw fastening, making it ideal for inline applications on conveyor belt assembly lines. This feature allows screw fastening to be done directly in-line rather than offline, significantly reducing handling time and increasing throughput.To accommodate the narrow spaces near connectors, the screw jaws are designed extra-thin to avoid interference with VGA, DVI, or similar connector structures, while still securely aligning with the screw holes for precise fastening.

Robot Type Automatic Screw Feeder

CM-TABLE

The SEALS CM-TABLE series is a programmable, robot-type automatic screw fastening solution designed to reduce manual labor and improve process consistency. By integrating Japanese JANOME desktop robots with precision screw jaws, torque-controlled electric/pneumatic screwdrivers, and intelligent screw feeding systems, CM-TABLE delivers high-speed, high-precision, and highly repeatable performance, ideal for high-mix, low-volume production environments.Screw fastening points and motion paths can be fully programmed and stored in up to 255 modules (or 30,000 points), allowing rapid changeover and support for flexible production lines. The system supports real-time error detection—including screw shortage, torque achievement, and stripped-thread detection (optional)—to ensure consistent quality and reliable operation.Depending on the application, SEALS offers both belt-driven XY systems with stepper motors and ball-screw-driven models powered by servo motors, providing optimal configuration for speed or precision. A range of working platform sizes (200×200mm to 510×510mm) is available to accommodate various workpiece sizes.With features like data collection, programmable control, and automation readiness, CM-TABLE helps standardize the screw fastening process and ensures high stability, independent of operator influence.