Customer Inquiry and Ordering Process Guide

To place an order, you are welcome to call us with your production line requirements and the details of the product to be fastened. Based on the information provided, our professional team will recommend the most suitable Automatic Screw Feeder.

Alternatively, you can fill out the online inquiry form on our website, and we will contact you as soon as possible.

To ensure an accurate and tailored quotation, we will first confirm key details with you—such as your industry, target markets, product application, and business model—before issuing an official quote.

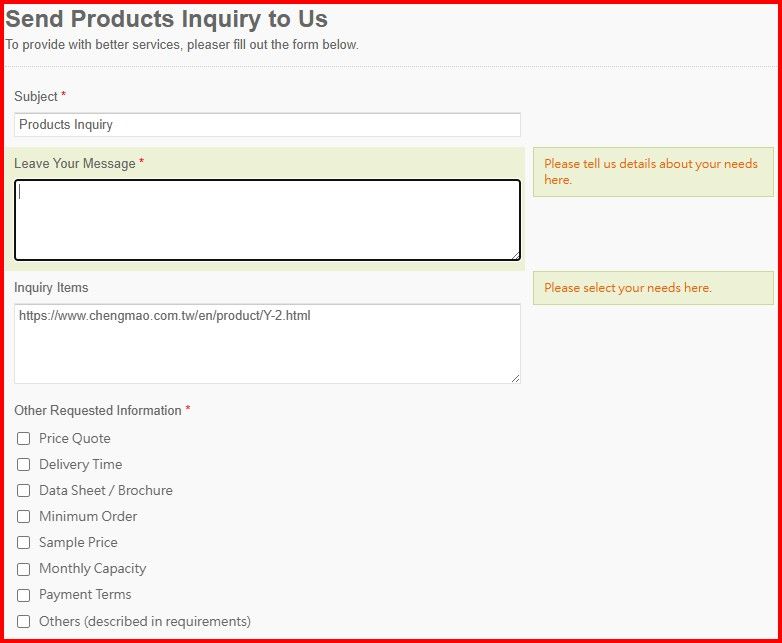

You may contact us by filling out the “Send Products Inquiry to Us” located at the bottom of each product page,

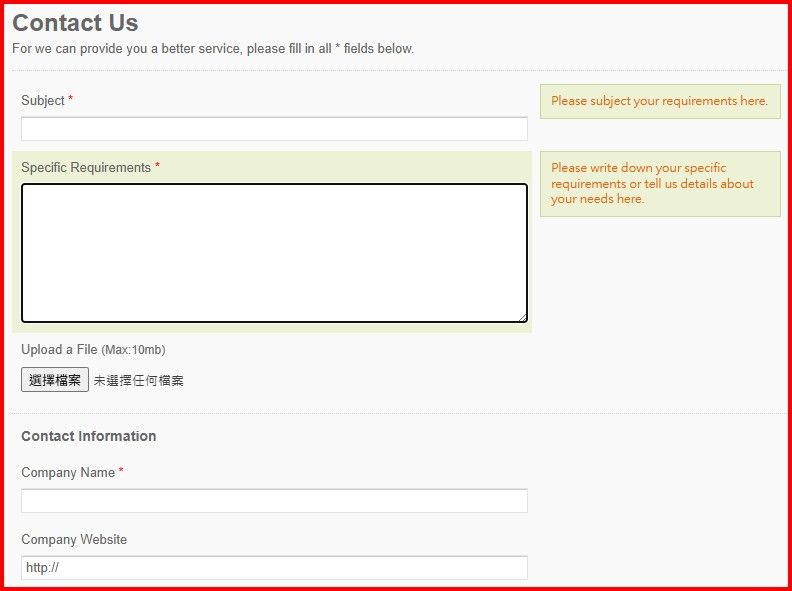

or by submitting the contact form on our “Contact Us” page.

For a more detailed overview of the ordering process, please click the image below to visit the “Ordering Process” information page.

- Related Products

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Automatic Nipple Feeder for Bicycle Rim

CM-A1, CM-A2, CM-A3, CM-A4

The SEALS Automatic Nipple Feeder is designed for G12 to G15 nipples, streamlining the lacing process for bicycle and e-bike rims. Nipples are delivered automatically and reliably to the driver tip, eliminating manual handling. With just one simple push, operators can complete the assembly with minimal effort—making the process accessible even for beginners. Featuring a compact structure, easy maintenance, and flexible screwdriver options, it adapts to single and double wall rims. Ideal for high-throughput, ergonomic production.

Air Nipper ( 27kg pressing power)

YM-30

SEALS YM-30 hand held air nipper has a 20mm diameter body. Its mini size body is very easy to hold and to reach a narrow space. It adopts S20 wire cutter (optional). The sharp shape of S20 is very useful for cutting legs of IC board. It use special treatment material to cut copper wire and iron wire.SEALS YM series handheld air nipper can help reducing operator fatigue and achieving ergonomic operation and higher productivity. Especially for repetitive crimping, cutting, squeezing, pressing applications, these jobs will be done by just a easy lever trigger. SEALS Air Nipper provides wide range options of air nippers and blades for variety industrial demand. Rotatable SEALS air nipper tool body is available for right hand and left hand operator.(Suitable for 0.8mm iron wire / 0.5mm iron wire)

Torque Reaction Arm ( 505mm working radius)

TR-350

Seals TR-350 Torque Reaction Arm has a 505mm work radius from the spindle base. With 365 degree rotation, TR-350 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-350A is for pneumatic tools only. And, TR-350AE is both for electric and pneumatic screwdriver.