Application

Summary

-

CM-300→Three-Axis Automatic Pin Insertion Machine – Woodworking Application

In this application, the processed material consists of long wooden workpieces commonly found in the woodworking industry. To enhance production efficiency and machining precision, the customer implemented SEALS customized automation equipment for system upgrading.

-

CM-30→Refrigerator & Appliance Assembly Application

In refrigerator assembly lines, fastening screws vertically on side panels is often labor-intensive and error-prone. The CM-30 Automatic Screwdriver, with its 90-degree press-down design and auto-feeding system, allows operators to complete fastening quickly and accurately with a simple downward press — boosting efficiency and reducing physical strain.

-

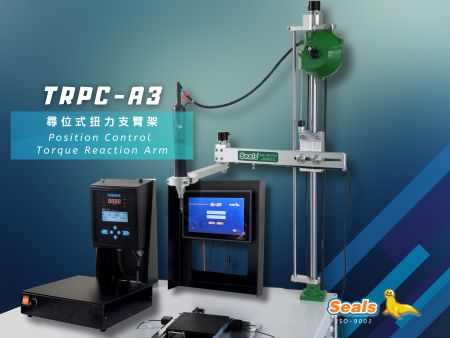

TRPC-A3→Low-error assembly processes

The TRPC series combines two major components: ➤A3 Torque Arm (350A3 / 650A3 / 900A3) – Available in three lengths to suit different workspace and workpiece sizes ➤CL-A3 Digital Management System – Offers touch-screen guidance, task control, and real-time torque monitoring Together, they form the TRPC-350A3 / 650A3 / 900A3 models, differentiated by torque arm length and coverage area.

-

CM-200→Eyeglass Hinge Screw Fastening

The CM-200 is specially designed for the screw fastening process at the hinge joints of eyeglass frames. Traditionally, this process required manual operation due to the small screw size and irregular frame structure, often leading to issues such as misaligned screws, over-tightening, or frame scratches, which affected quality consistency. By integrating a dual-axis screwdriving mechanism with an automatic index table and gripper system, the CM-200 enables precise positioning and simultaneous fastening of dual screws. This significantly reduces cycle time per unit while minimizing operator skill dependency—making it ideal for high-volume eyeglass frame production lines. This system has been successfully implemented by OEM factories and private label eyeglass brands, helping them optimize manpower allocation, increase production efficiency, and achieve consistent product quality with a high yield and low defect rate.

-

CM-500→Gas Meter Top & Bottom Cover

Designed to address the precise and repetitive demands of gas meter cover assembly, the CM-500 offers an efficient and reliable automatic fastening solution. Equipped with five servo-controlled screwdrivers, the machine fastens five screws simultaneously, making it ideal for securing gas meter top covers to their bases. The integrated automatic screw feeder eliminates the need for manual screw placement, saving time and ensuring consistent quality across each unit. Customizable jigs allow for quick adaptation to different gas meter sizes, while a built-in light curtain sensor enhances operator safety. Whether you’re handling small batch runs or large-scale production, the CM-500 is built to deliver consistent, professional results.

-

SB/HSB Series→Line Organization and Labor-Saving Applications

In conventional production lines, tools are often placed on workbenches or floors, occupying valuable workspace and creating clutter. Operators must repeatedly bend or lift to access tools, leading to muscle fatigue and even occupational injuries. Additionally, accidental tool drops not only increase the risk of damage but also compromise operational safety. With the SEALS SB / HSB Spring Balancer Series, tools can be suspended at the optimal height in a “weightless state,” allowing effortless and smooth operation. The built-in safety wire prevents tool drops, keeping the workspace neat and organized while enhancing safety. Covering a full load range of 0.3–120 kg, the series accommodates a wide variety of tools—from electric screwdrivers, glue guns, and drills to spot welders and heavy polishing machines—making it especially suitable for assembly lines and heavy-duty applications.

-

TAB/THB Series→Hose Management & Air Supply Integration

《Case Description》 The TAB / THB Series Hose Balancers are mainly applied in production lines for the suspension and air supply management of pneumatic tools. The TAB Series (hose inner diameter 6.5 mm) is suitable for small pneumatic tools such as screwdrivers, cutters, and light pneumatic fixtures. The THB Series (hose inner diameter 8 mm) is designed for high air consumption tools such as impact wrenches, grinders, and riveters. Traditional pneumatic tools often suffer from messy hoses on the ground, which affect both efficiency and safety. By using hose balancers, hoses are suspended overhead, preventing tripping hazards, accidental pulling, or unstable air supply. The smooth retraction and adjustable tension allow operators to freely control their pneumatic tools, achieving an organized production line and higher efficiency.

-

CM-A1~A4→Automatic Nipple Feeder – Bicycle Rim Assembly Line

《Case Description》 In bicycle rim assembly lines, traditional manual methods require workers to repeatedly pick up G12–G15 nipples and fasten them one by one. This process is not only time-consuming but also prone to issues such as dropped parts, mismatched sizes, and inconsistent quality. These challenges become more pronounced in high-volume production, often creating efficiency bottlenecks and increasing rework rates. The SEALS CM-A1 ~ A4 Automatic Nipple Feeder for bicycle rims automatically delivers nipples precisely to the screwdriver tip. Operators only need to align the hole and push lightly to complete fastening. This design effectively shortens cycle times, enhances overall line stability, and reduces quality variations caused by operator skill differences. Actual application results show that production efficiency improves by more than 30%, training time for new staff is cut in half, and defect rates are significantly reduced. This helps production lines respond quickly to market demand while achieving the dual goals of high efficiency and high quality.

-

CM-200→Compressor Connecting Rod Nut Tightening Application

《Case Description》 In the past, the nut-tightening process for compressor connecting rods was mostly performed manually, requiring operators to apply balanced torque on both sides simultaneously. Since the nuts are fixed on the workpiece, completing the tightening in one smooth action is difficult. Long periods of manual operation increase operator fatigue, and the tightening force varies from person to person, often resulting in inconsistent torque, uneven tightening depth, and unstable cycle times. To address these issues, we designed a dedicated automated tightening machine to ensure both nuts on the connecting rod can be tightened synchronously under identical conditions. The CM-200 adopts a dual-spindle synchronous tightening design. Once the workpiece is placed on the fixture, the left and right clamp arms secure it in position. After pressing the dual-start buttons, both nuts are tightened simultaneously, ensuring consistent torque and improved assembly quality. The machine features a stable clamping mechanism and controlled stroke, effectively reducing errors caused by manual operation. For rework or correction, the reverse-tightening function can be activated to quickly loosen the nuts. The streamlined process shortens the fastening cycle and significantly improves quality stability, making the CM-200 an ideal solution for connecting-rod assembly lines. This system has already been successfully implemented in multiple compressor-related manufacturing facilities, helping customers reduce manual workload, increase production efficiency, and enhance fastening consistency. Actual production feedback further confirms its stability and excellent performance as a replacement for manual operations.

-

YM-30 + OTHERS → Medical Application Air Nipper

《Case Description》 A Critical Tool for Ultra-Fine Wire Insertion — Application of the Customized YM-30 Air Holding Nipper in Implantable Electronic Medical Devices As implantable electronic medical devices continue to evolve toward miniaturization, higher density, and increased precision, the dimensions of wires and terminals used in neural stimulators, sensing electrodes, and related electronic modules have been reduced to levels that are difficult to handle using conventional electronic assembly methods. In such advanced medical manufacturing processes, the ability to stably handle ultra-fine wires at hair-scale diameters, while ensuring assembly consistency and reliability, has become a critical factor affecting overall product quality. 【Practical Manufacturing Challenges in Implantable Electronic Medical Devices】 During the manufacturing of implantable electronic medical devices, ultra-fine wires must often be precisely inserted into micro-sized metallic tubular terminals before subsequent fixation or encapsulation processes. In this application, the corresponding terminal specifications are as follows: ◎Tubular metal terminal ◎Outer diameter: approximately Ø0.26 mm ◎Length: approximately 1.5 mm The wires themselves are only about 1–2 strands of hair in diameter, soft in texture and prone to uncontrolled movement. Combined with the extremely small size of the tubular terminals, wire insertion must be performed under a microscope. When relying solely on fingers or general-purpose tools, the wires are highly susceptible to bending, slipping, or misalignment, resulting in unstable processes and potential material damage. 【Why a Dedicated Wire Holding and Guiding Tool Is Required】 In such manufacturing scenarios, the primary purpose of the tool is not to cut the wire, but to: ◎Stably hold ultra-fine wires ◎Control wire direction and insertion angle ◎Assist smooth and accurate insertion into micro tubular terminals ◎Reduce heavy dependence on operator experience and manual skill Without dedicated tooling support, it is difficult to maintain a high success rate and consistent quality in wire insertion processes, making stable production and scalability challenging.