Torque Reaction Arm ( 505mm working radius)

TR-350

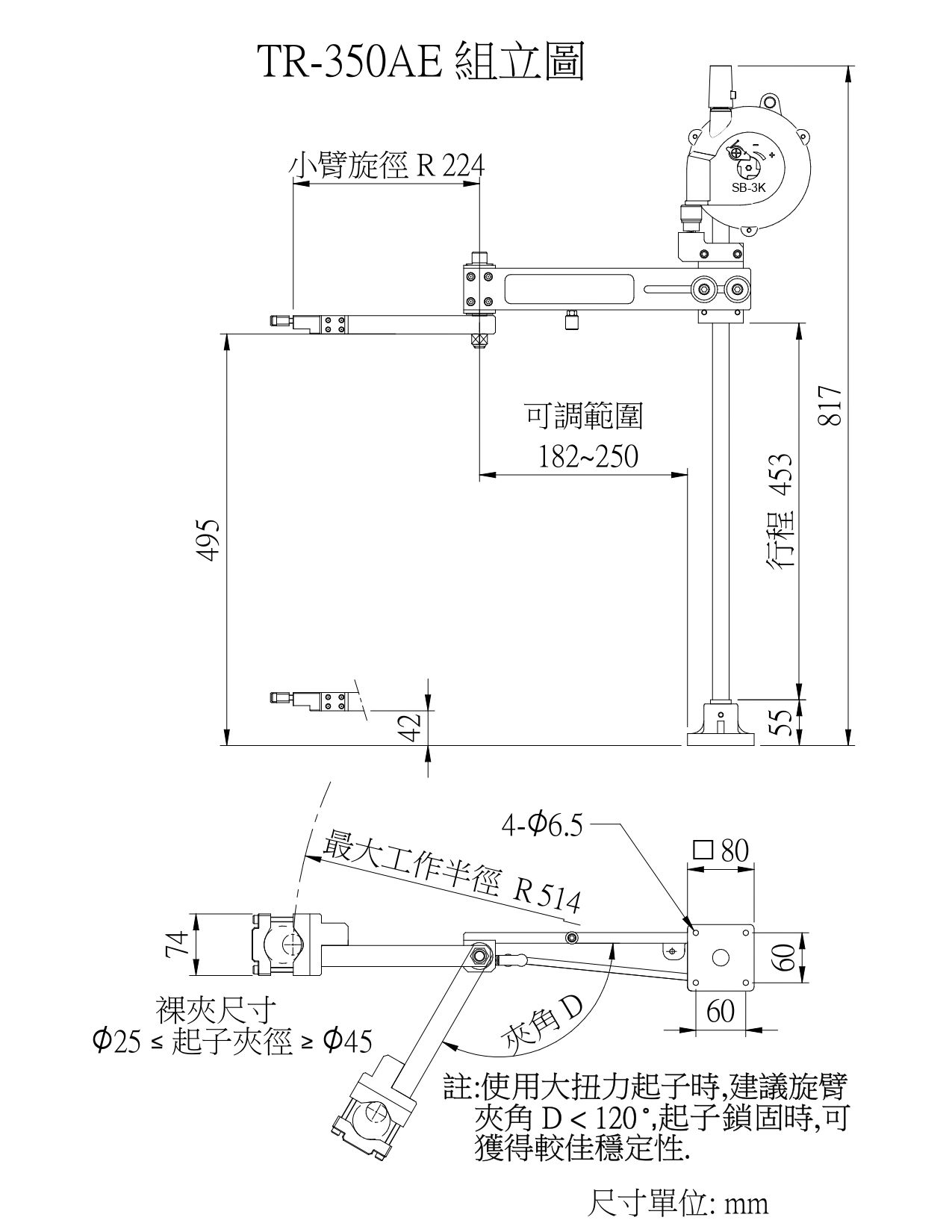

Seals TR-350 Torque Reaction Arm has a 505mm work radius from the spindle base. With 365 degree rotation, TR-350 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.

TR-350A is for pneumatic tools only. And, TR-350AE is both for electric and pneumatic screwdriver.

Nickname

Torque Arm

Features

It is designed to avoid for injuries caused by repetitive work and overusing the arm can occur in daily work activities. We provide the opportunity to implement ergonomic improvements to the manufacturing process. This torque reaction arm removes torque twisting and weight loading to create a safe work environment.

Specification

- 1. Maintains tool in a constant vertical position.

- 2. Exclusive height adjustment.

- 3. 360° swivel.

Specification

| Model No. | TR-350A | TR-350AE |

|---|---|---|

| Tool Installment | Air Connector(A Type) | Clamp(AE Type) |

| Max. Working Area | R508 | R508 |

| Vertical Stroke | 370 mm | 370 mm |

| Screwdriver Type | Pneumatic | Electric / Pneumatic |

| Screwdriver Weight | < 1 kgs | < 0.8 kgs |

Applications

- Screwdriving.

- Drilling and Tapping.

- Automatic Screw Feeding.

- Impact Wrenches.

- Impact Tools.

- Pulse Tools.

- C type table clip.

- Automatic Screw horizontal seat.(TR series)

Accessory

- Dimensions

- Gallerys

- Movies

- Related Products

Torque Linear Arm ( 182-561mm working radius)

TA-300S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loadsAfter clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1122mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws.This Torque Reaction Arm can effectively reduce the space requirement of the workplace.With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment.It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Automatic Screw Feeder with Lever-Activating Design

CM-40T

The SEALS CM-40T Automatic Screw Feeder is designed based on the principles of speed, stability, and convenience. It integrates pneumatic or electric torque-controlled screwdrivers, precision-engineered jaws, and a reliable horizontal feeding mechanism to significantly improve fastening speed and overall production efficiency.The system features an ergonomic lever-activated design that allows the operator to simply press the lever, prompting the screwdriver bit to automatically push downward and complete the fastening process. This design minimizes the required press stroke, reduces operator fatigue, and enhances productivity. The jaw is engineered to avoid direct pressure on the surface of the workpiece, effectively protecting product finishes and coatings from damage.To meet the demands of automated manufacturing, the CM-40T can also be integrated into various automation platforms such as XY tables, SCARA robots, 6-axis robotic arms, or other custom automatic assembly systems. The automation-ready version supports input/output signal communication and can seamlessly interface with major control systems.

C Shaped Table Clamps - Clamp Range : 13.5-75mm

TA-C

The TA-C C Shaped Table Clamp is a dedicated accessory for SEALS torque reaction arms, designed to provide flexible mounting solutions without being restricted by table design. With just a 6mm hex wrench, operators can quickly secure the clamp onto any workbench, ensuring firm and stable installation without drilling holes or damaging the table surface.SEALS offers two installation methods: ●C Shaped Table Clamp → Recommended for light-torque screwdrivers, offering quick setup and easy relocation. ●Upright Base → Recommended for high-torque screwdrivers, providing greater rigidity and stability for heavy-duty applications.The TA-C clamp is compatible with TA-300, TA-600, TR-350, TR-650, TA-300S, and TA-600S, making it highly versatile for a wide range of production environments. Its rugged, durable construction ensures long service life and consistent performance under repeated operations.

Automatic Screw horizontal seat-TR series torque reaction arm

TR-LS

The TR-LS Automatic Screw Horizontal Seat is a dedicated accessory for SEALS TR Series Torque Reaction Arms (TR-350, TR-650), specifically engineered for production lines requiring multi-angle and versatile fastening operations.With the TR-LS, operators can seamlessly switch from vertical to horizontal screwdriving, enabling greater flexibility when handling products with diverse fastening orientations.Designed with ease of installation, structural stability, and operational flexibility in mind, the TR-LS requires only a hexagonal wrench for quick mounting or removal. This simple yet efficient design minimizes downtime and enhances production adaptability when shifting between workpieces or adjusting assembly line setups.When installed, the TR-LS ensures high efficiency and accuracy even in tight spaces or positions where vertical fastening is impractical. By working in tandem with the TR torque arm’s reaction force absorption mechanism, it reduces torque feedback, preventing operator fatigue and ensuring stable, consistent fastening quality during long-term, high-frequency operations.The TR-LS also adds strategic value to modern manufacturing: whether on manual workstations, semi-automated lines, or in integration with automatic screw feeders, it provides enhanced flexibility and reliability.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.