Purpose of a Torque Reaction Arm

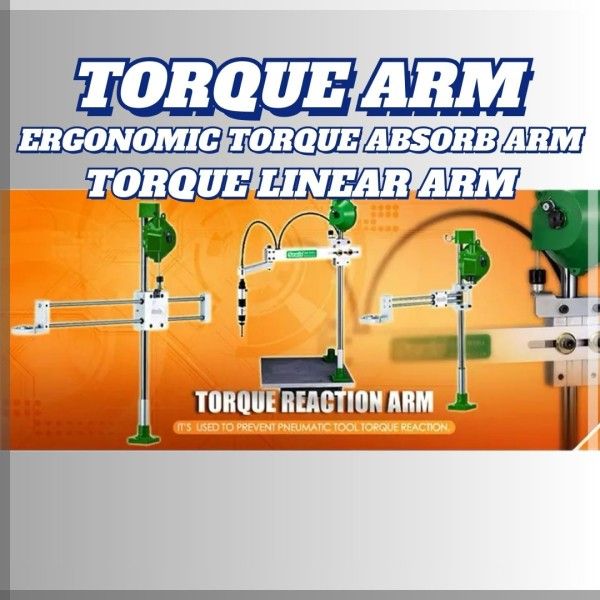

Q: What Is the Purpose of a Torque Reaction Arm?

A:A torque reaction arm is designed to reduce operator fatigue and improve screw-fastening accuracy, especially when working with heavy tools or high-torque applications. It supports the tool’s weight and absorbs torque reaction to ensure consistent and precise fastening.

Advantages of Using a Torque Reaction Arm

✔ Absorbs instantaneous torque reaction, reducing strain on the operator’s wrist.

✔ Reduces the load from tool weight and torque force, making long-term operation less fatiguing.

✔ Maintains excellent vertical alignment, corrects user posture, and ensures perpendicular screw insertion to enhance fastening quality.

✔ Freely adjustable in height and vertically, with 360° horizontal rotation.

✔ Easy to operate, significantly improves work efficiency.

Compared to Traditional Handheld Operation

✘ Operator fatigue from continuous handheld use may lead to work-related injuries.

✘ Inexperienced or tired workers may cause misaligned fastening and poor product quality.

- Related Products

-

-

Torque Reaction Arm ( 505mm working radius)

TR-350

Seals TR-350 Torque Reaction Arm has a 505mm work radius from the spindle base. With 365 degree rotation, TR-350 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator. TR-350A is for pneumatic tools only. And, TR-350AE is both for electric and pneumatic screwdriver.

-

Torque Reaction Arm ( 750mm working radius)

TR-650

Seals TR-650 Torque Reaction Arm has a 750mm work radius from the spindle base. With 365 degree rotation, TR-650 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator. TR-650A is for pneumatic tools only. And, TR-650AE is both for electric and pneumatic screwdriver.

-

Torque Linear Arm ( 182-561mm working radius)

TA-300S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loads After clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1122mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws. This Torque Reaction Arm can effectively reduce the space requirement of the workplace. With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment. It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

-

Torque Linear Arm ( 236-744mm working radius)

TA-600S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loads After clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1488mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws. This Torque Reaction Arm can effectively reduce the space requirement of the workplace. With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment. It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

-