Programmable VGA, DVI Card Automatic Screw Feeder Machine

CM-40AUT

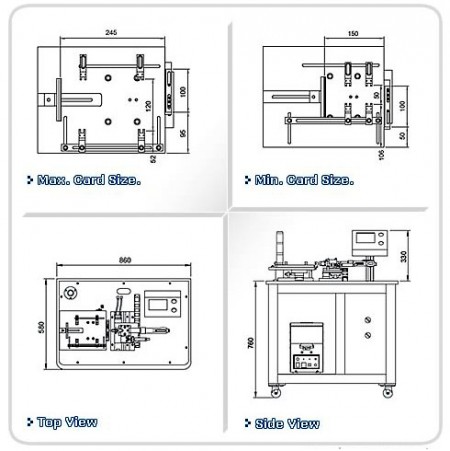

The SEALS CM-40AUT is a professional, programmable automatic screw feeder specifically engineered for assembling VGA, DVI, and other interface cards. Designed to handle two or four standoff screws per board, it offers a teachable positioning system, allowing operators to store up to 200 sets of fastening positions—ideal for high-mix, low-volume production environments.

To accommodate narrow screw locations near VGA and DVI connectors, CM-40AUT adopts extra-thin jaws that ensure accurate alignment without interference. Similar to other SEALS models such as CM-30T, CM-40T, and CM-B1, the CM-40AUT features an ergonomic auto bit-pushing mechanism, which enables smooth horizontal fastening without requiring operators to manually press or hold the PCB—making it especially suitable for use on conveyor belt systems.

For integration into fully automated production lines, both CM-40AUT and CM-B1 models can be incorporated with XY tables, SCARA robots, 6-axis robots, or other customized auto assembly equipment. The automation versions also support I/O signal communication, allowing seamless control and feedback with central control systems.

Nickname

Automatic Screw Feeding Machine for stand off screw

Features

1. Designed for hexagonal standoff screws.

2. Optimized for VGA, DVI, and similar graphic card interfaces.

3. Accommodates various card sizes with easy-to-adjust fixture design.

4. Standard working range up to 150mm.

5. Stores up to 200 fastening point modules, ideal for flexible manufacturing.

6. Module changeover completed in under 1 minute.

7. Capable of fastening 4 screws within 10 seconds.

8. Uses torque-controlled electric screwdrivers for precise and reliable fastening.

9. Includes screw shortage detection and alert function.

10. Built-in stripped-thread detection for error prevention.

11. Torque achievement verification ensures process quality.

12. One operator can manage 2–4 machines simultaneously to maximize output.

13. User-friendly touchscreen interface for easy setup and fast operation.

- Movies

- Related Products

Robot Type Automatic Screw Feeder

CM-TABLE

The SEALS CM-TABLE series is a programmable, robot-type automatic screw fastening solution designed to reduce manual labor and improve process consistency. By integrating Japanese JANOME desktop robots with precision screw jaws, torque-controlled electric/pneumatic screwdrivers, and intelligent screw feeding systems, CM-TABLE delivers high-speed, high-precision, and highly repeatable performance, ideal for high-mix, low-volume production environments.Screw fastening points and motion paths can be fully programmed and stored in up to 255 modules (or 30,000 points), allowing rapid changeover and support for flexible production lines. The system supports real-time error detection—including screw shortage, torque achievement, and stripped-thread detection (optional)—to ensure consistent quality and reliable operation.Depending on the application, SEALS offers both belt-driven XY systems with stepper motors and ball-screw-driven models powered by servo motors, providing optimal configuration for speed or precision. A range of working platform sizes (200×200mm to 510×510mm) is available to accommodate various workpiece sizes.With features like data collection, programmable control, and automation readiness, CM-TABLE helps standardize the screw fastening process and ensures high stability, independent of operator influence.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.