Automatic Nipple Feeder for Motorcycle Rim

CM-A8, CM-A9, CM-A10, CM-A11, CM-A12

For Lacing Nipple size from G8 ~ G11 into motorcycle rim. The nipple will be send to the driver end fast and steadily. The operation just spend they time in aiming the hole for rim and collecting the spoke. Just one push stroke. Simplify the process even the new coming can reach the performance of skillful operator.

Nickname

Automatic Nipple Lacing for Motorcycle Rim

Features

1. Without Manual Handling of the Nipple.

The nipple will be send to the driver end fast and steadily. The operation just spends they time in aiming the hole for rim and collecting the spoke. Just one push stroke. Simplify the process even the new coming can reach the performance of skillful operator.

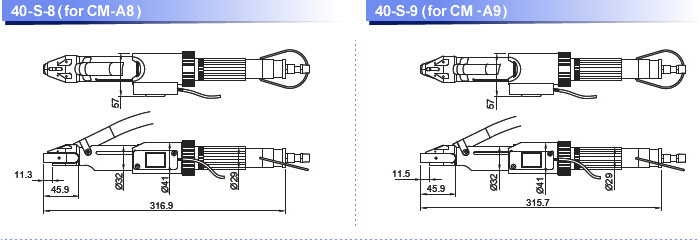

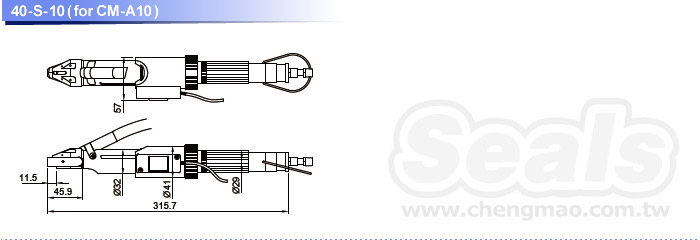

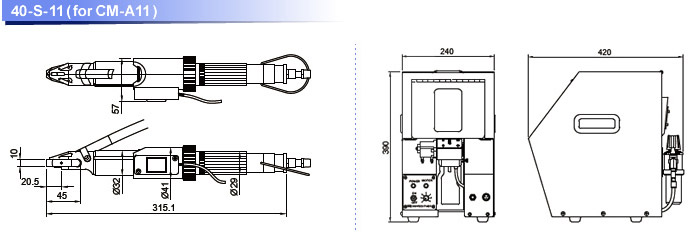

2. Exchangeable Screwdriver Sets for Different Deep of Rim

There are three options of screwdriver sets to fit different application of variety type of rim.

The feeder is the same, but you just change the screwdriver for single wall of rim and different depth of double wall of rim. It only takes one minute to change the screwdriver set. Easy, Flexible, Economic!

3. For Motorcycle and Bicycle Industry

These machine have different models size for Nipple G8, G9, G10, G11, G12, G13, G14, G15.

Specification

- Without the trouble of manual handling nipples, the nipple is send to the driver tip fast and steadily. Assembly work can be completely simply by a slight push.

- The specific Screwdriver Set is suitable for the concave environment around drilling hole in the Motorcycle rim.

- It achieves higher production efficiency at 40 rims per hour. Compact mechanical structure achieves easier maintenance while providing lower maintenance cost and shorter investment return.

- Spring Balancer is equipped for operating the Pneumatic Screwdriver spritely and flexibly without burden.

- The bit is provided with 3mm Pin to achieve appropriate driving depth for the Nipple so as to avoid unbalanced rim fastening.

- It is provided with CM-T2 Wheel Assembly Table and is suitable for various kinds and sizes of rims. Further, the high-low position is also adjustable according to the respective application habitude. Besides, the Hub Holding Mode can also be replaced according to different hub pattern.

- It is provided with CM-T3 Machine Table to achieve neat and aesthetic look of the production line. Further, the Suspension Arm is also provided for installing the Spring Balancer.

| Model | CM-A8 | CM-A9 | CM-A10 | CM-A11 |

|---|---|---|---|---|

| Rim Type | Motorcycle | |||

| Nipple No. | 8G | 9G | 10G | 11G |

| Wall Type | Single Wall | |||

| Feeding (pcs/min) | 30 | 30 | 30 | 30 |

| Capacity (pcs) | 600 | 750 | 1000 | 1650 |

| Voltage | 220V; Single Phase | |||

| Air Pressure | 5kg/cm² | |||

| L / W / H | 42 x 24.5 x 39 cm | |||

| Weight (Net) | 23 kgs | |||

- Dimensions

- Movies

- Related Products

Floor Type Wheel Building Stand

CM-T2

CM-T2 is a working table for bicycle and motorcycle wheel assembly. With adjustable support arm, it is suitable for variety of wheel size. And, with rotateable roller, SEALS CM-T2 provides easier nipple lacing operation. By adopting SEALS CM-A1 automatic nippler feeder, it can improve wheel nipple and spoke lacing speed up to 320 rims per eight hours. Meanwhile, SEALS CM-T3, stand for nipple feeder is also for option.

Automatic Nipple Feeder for Bicycle Rim

CM-A1, CM-A2, CM-A3, CM-A4

The SEALS Automatic Nipple Feeder is designed for G12 to G15 nipples, streamlining the lacing process for bicycle and e-bike rims. Nipples are delivered automatically and reliably to the driver tip, eliminating manual handling. With just one simple push, operators can complete the assembly with minimal effort—making the process accessible even for beginners. Featuring a compact structure, easy maintenance, and flexible screwdriver options, it adapts to single and double wall rims. Ideal for high-throughput, ergonomic production.

- Files Download

Automatic Nipple Feeder Catalog

SEALS Helpful bicycle rim and motorcycle rim assembly machine. These machine assembly nipple into spoke by feeding nipple into the top the screwdriver set to let the operator lacing the nipple into spoke quickly, easily, stably.