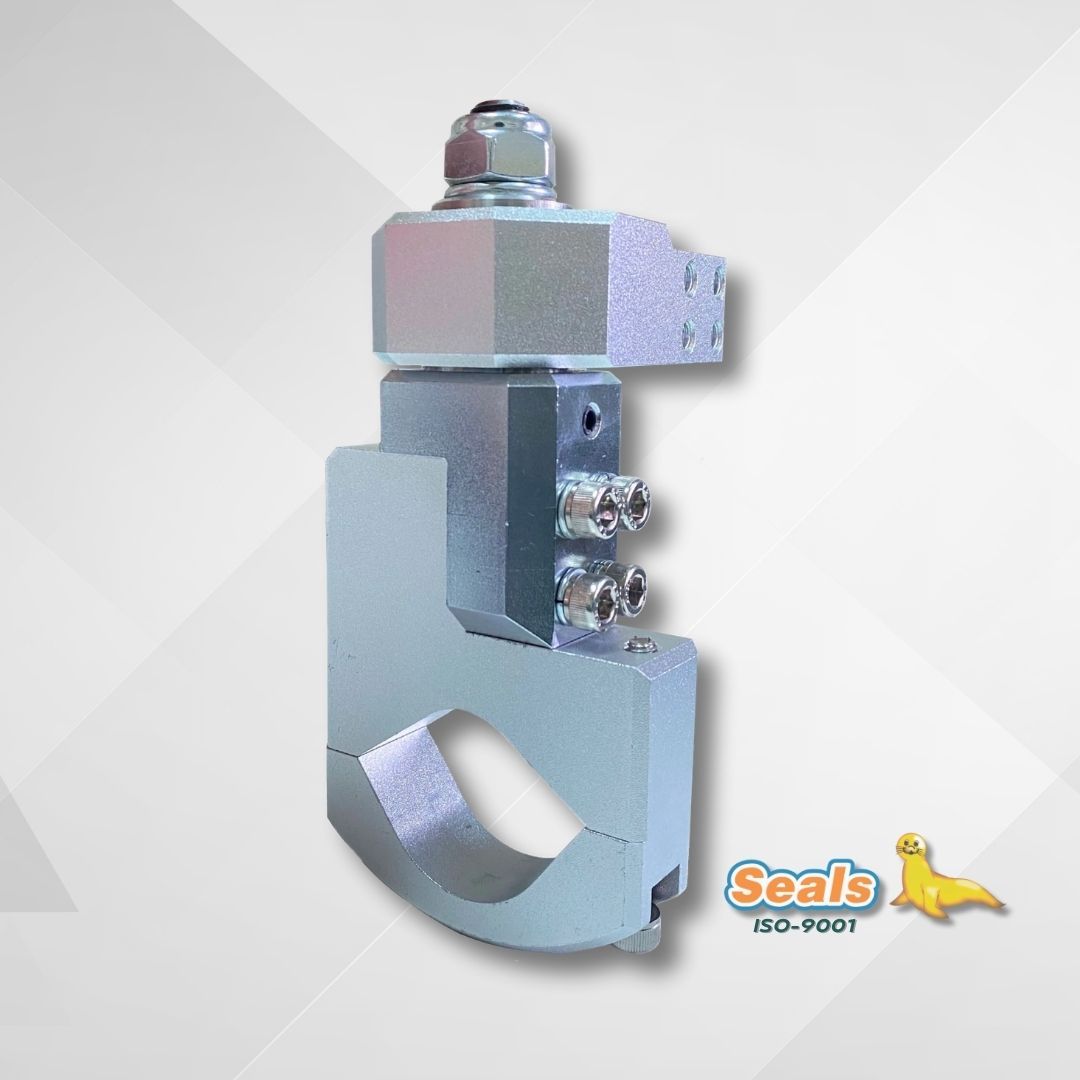

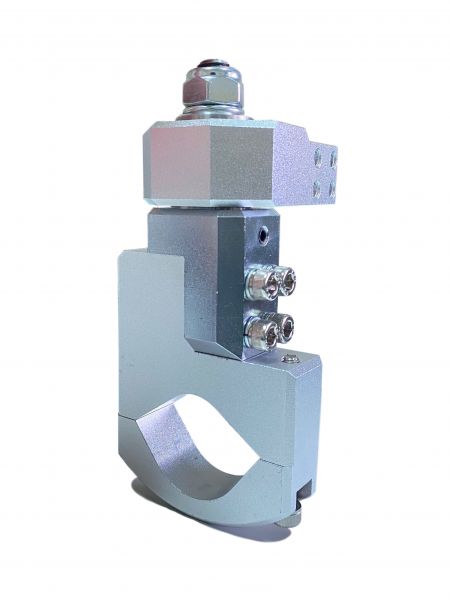

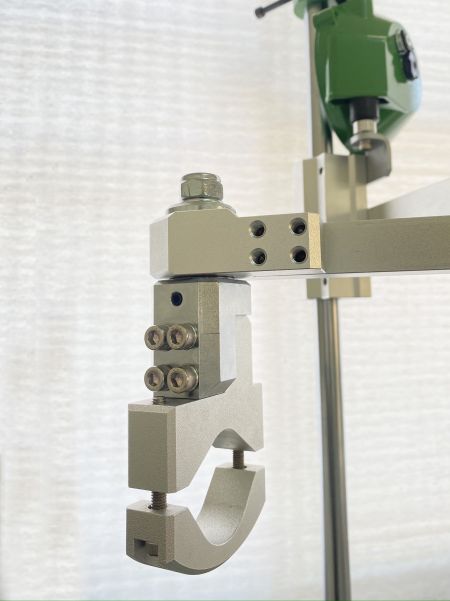

Automatic Screw horizontal seat-TR series torque reaction arm

TR-LS

The TR-LS Automatic Screw Horizontal Seat is a dedicated accessory for SEALS TR Series Torque Reaction Arms (TR-350, TR-650), specifically engineered for production lines requiring multi-angle and versatile fastening operations.

With the TR-LS, operators can seamlessly switch from vertical to horizontal screwdriving, enabling greater flexibility when handling products with diverse fastening orientations.

Designed with ease of installation, structural stability, and operational flexibility in mind, the TR-LS requires only a hexagonal wrench for quick mounting or removal. This simple yet efficient design minimizes downtime and enhances production adaptability when shifting between workpieces or adjusting assembly line setups.

When installed, the TR-LS ensures high efficiency and accuracy even in tight spaces or positions where vertical fastening is impractical. By working in tandem with the TR torque arm’s reaction force absorption mechanism, it reduces torque feedback, preventing operator fatigue and ensuring stable, consistent fastening quality during long-term, high-frequency operations.

The TR-LS also adds strategic value to modern manufacturing: whether on manual workstations, semi-automated lines, or in integration with automatic screw feeders, it provides enhanced flexibility and reliability.

Nickname

Screwdriver horizontal fixing seat, horizontal clamping seat, Screwdriver horizontal clamping seat

Applications

Electronics Assembly – Ideal for horizontal fastening of PCBs and communication equipment

Automotive & Motorcycle Parts – Supports fastening tasks in side-positioned or horizontal screw locations

Hardware & Industrial Assembly – High-frequency, multi-angle fastening operations

Automation Integration – Suitable for semi-automated or fully automated screw feeding systems

Features

1. Versatile Operation–Switch freely between vertical and horizontal fastening modes

2. Quick Installation & Removal–Requires only a hex wrench, no special tools needed

3. Reduced Fatigue–Maintains torque absorption to protect the operator

4. Stable and Precise–Ensures fastening accuracy in horizontal applications

5. Perfect Compatibility–Specifically designed for TR-350 and TR-650 torque reaction arms

6. Wide Applications–Compatible with electric/pneumatic screwdrivers, drilling & tapping tools, automatic screw feeders, impact and pulse tools

Applications

- Screwdriving.

- Drilling and Tapping.

- Automatic Screw Feeding.

- Impact Wrenches.

- Impact Tools.

- Pulse Tools.

- Gallerys

- Related Products

Torque Reaction Arm ( 505mm working radius)

TR-350

Seals TR-350 Torque Reaction Arm has a 505mm work radius from the spindle base. With 365 degree rotation, TR-350 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-350A is for pneumatic tools only. And, TR-350AE is both for electric and pneumatic screwdriver.

Torque Reaction Arm ( 750mm working radius)

TR-650

Seals TR-650 Torque Reaction Arm has a 750mm work radius from the spindle base. With 365 degree rotation, TR-650 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-650A is for pneumatic tools only. And, TR-650AE is both for electric and pneumatic screwdriver.

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Automatic Screw horizontal seat-TA series torque reaction arm

TA-LS

The TA-LS Automatic Screw Horizontal Seat is a dedicated accessory for the SEALS Torque Reaction Arm series, designed for models TA-300, TA-300S, TA-600, and TA-600S. It enables screwdrivers originally set for vertical fastening to be easily converted into horizontal operations, expanding flexibility on assembly lines.Featuring a quick hex-wrench installation design, the TA-LS allows operators to switch between vertical and horizontal modes without complicated adjustments. This adaptability makes it ideal for production lines that handle different products or require frequent process changes.By providing ergonomic working angles, the TA-LS reduces operator fatigue and prevents fastening errors such as cross-threading or stripping. At the same time, it retains the original reaction force absorption capability of the torque arm, ensuring operator safety and long-term productivity.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.