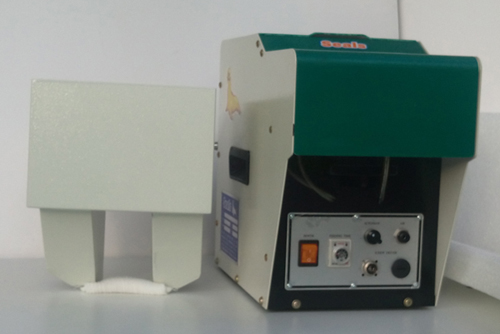

Automatic Screw Feeder with Lever-Activating Design

CM-40T

The SEALS CM-40T Automatic Screw Feeder is designed based on the principles of speed, stability, and convenience. It integrates pneumatic or electric torque-controlled screwdrivers, precision-engineered jaws, and a reliable horizontal feeding mechanism to significantly improve fastening speed and overall production efficiency.

The system features an ergonomic lever-activated design that allows the operator to simply press the lever, prompting the screwdriver bit to automatically push downward and complete the fastening process. This design minimizes the required press stroke, reduces operator fatigue, and enhances productivity. The jaw is engineered to avoid direct pressure on the surface of the workpiece, effectively protecting product finishes and coatings from damage.

To meet the demands of automated manufacturing, the CM-40T can also be integrated into various automation platforms such as XY tables, SCARA robots, 6-axis robotic arms, or other custom automatic assembly systems. The automation-ready version supports input/output signal communication and can seamlessly interface with major control systems.

Nickname

Automatic Screw Fastening Machine

Features

1. Ergonomic lever-activated design for effortless and intuitive operation.

2. Screw fastening is completed automatically upon pressing the lever.

3. Fully automatic screw feeding eliminates manual screw handling and alignment.

4. Compatible with screw sizes ranging from 2.5mm to 6.0mm.

5. Fastening speed up to 20–30 screws per minute.

6. Torque-controlled driver ensures consistent and high-quality fastening.

7. Uses durable and reliable Japanese-made pneumatic/electric screwdrivers.

8. Smart feeding system saves energy and prevents material shortage.

9. The bit automatically ejects screws; jaws do not contact the workpiece surface, preventing scratches or stress.

10. Includes spring balancer for weight-free handheld operation.

11. Compatible with TR-350A, TR-650A, TA-300, TA-600, TM-6, THA, THB, and more for flexible configurations.

Specification

- Voltage: 220V, Single Phase

- Air Pressure: 5.5 kg / cm² / 85PSI

- L / W / H: 45 / 24 / 39 cm

- Net Weight / Gross Weight: 26 kg / 35 kg

- Capacity: 30 pcs/min.

- Torque: Refer to screwdriver capacity

- Volume: M3 x 15 2000 pcs

- Driver Option : Sumake, Uryu, M&L (Air Screwdriver) or Sumake, Kilews Electric, Delvo (Electric Screwdriver)

Available Screw Chart

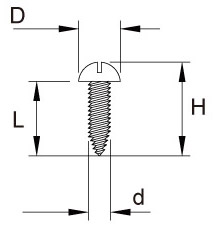

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

⚠ Special specification screws not listed in this table may also be compatible. For further information, please contact our service personnel.

| Pan Head Round Head | Flat Head Oval Head | Binding Head | Truss Head | Max. L Dimension (L) | ||||

|---|---|---|---|---|---|---|---|---|

| Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | |

| 4.6 | 8 | 4.9 | 8 | 5.2 | 9 | 12 | ||

| 4.5 | 8 | 5.0 | 8 | 5.3 | 8 | 5.7 | 10 | 16 |

| 5.5 | 9 | 6.0 | 9 | 6.3 | 9 | 6.9 | 11 | 20 |

| 6.0 | 9 | 7.0 | 10 | 7.3 | 10 | 8.1 | 12 | 22 |

| 7.0 | 10 | 8.0 | 11 | 8.3 | 11 | 9.4 | 13 | 22 |

| 8.0 | 11 | 9.0 | 12 | 9.3 | 12 | 10.6 | 14 | 22 |

| 9.0 | 12 | 10.0 | 13 | 10.3 | 13 | 11.8 | 15 | 22 |

| 10.5 | 13 | |||||||

Screwdriver Optional

The choice of screwdriver plays a critical role in fastening quality and operational efficiency.

We offer a curated selection of high-performance brands, including URYU, SUMAKE, and M&L torque-controlled pneumatic screwdrivers, as well as SUMAKE, KILEWS, and Delvo torque-controlled electric screwdrivers—providing flexibility to suit diverse application needs.

⚠ Note:

The torque values listed are provided by the screwdriver manufacturers and are based on test results measured using torque testers. Actual torque output during application may vary depending on the material, screw type, and fastening conditions.

▷ Compatibility Notice:

Other brands and specifications may also be supported, subject to project-based evaluation for integration feasibility.

Accessory

Extension Hopper: Part No. RH-3 (Optional)

- Gallerys

- Movies

- Related Products

Fasten Stroke Cylinder Equipment

TM-6

The SEALS Fasten Stroke Cylinder Equipment integrates a pneumatic screwdriver module onto a cylinder-driven slide system. Activated via automatic control, foot switch, or foot valve, it enables smooth, hands-free screw fastening. Operators simply place the workpiece into the fixture, and the system completes the fastening process efficiently, accurately, and with consistent quality—ideal for reducing manual workload and enhancing production stability.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.