Vibration Bowl Type Automatic Screw Feeder

CM-501

The SEALS CM-501 vibration bowl type automatic screw feeder is designed for speed, stability, and convenience. With a maximum feeding rate of 50 screws per minute, it significantly improves fastening efficiency in production environments.

The system supports a wide range of screw sizes, from M1.0 to M8, and screw lengths up to 30 mm. Compared to sword-type feeders, the vibration bowl design provides a larger screw capacity due to its built-in tank, making it suitable for long-duration operations with fewer refills.

Integrated with a pneumatic or electric torque-controlled screwdriver and a custom precision jig, the CM-501 offers stable, reliable fastening performance across various applications such as electronics, aluminum products, plastic components, and hardware assemblies.

Its simplified mechanical structure allows for easier maintenance and long-term operational stability. The jig and feeding configuration can also be customized to match specific screw dimensions and workpiece requirements.

Nickname

Automatic Screw Fastening Machine / Vibration Type

Features

1. High Productivity

Fastening rate up to 30 screws per minute—eliminating manual screw pickup and reducing cycle time.

2. Reliable Screw Feeding

Vibration bowl delivers up to 50 screws per minute, ensuring constant availability at the fastening point.

3. Wide Screw Compatibility

Supports screw sizes from M1.5 to M8, suitable for various assembly requirements.

4. Consistent Fastening Quality

Equipped with Japanese torque-controlled auto-stop screwdrivers (pneumatic/electric), ensuring stable performance.

5. Tailored to Your Needs

Each unit is custom-built to match the customer’s screw type and workpiece requirements for optimal performance.

Specification

- Voltage: 220V, Single Phase

- Air Pressure: 5.5kg / cm² (=0.54MPa)

- L / W / H: 43 / 39 / 38 cm

- Net Weight / Gross Weight: 50 kg / kg

- Capacity: 60 pcs/min.

- Torque: Refer to screwdriver capacity

- Volume: 1300 c.c.

- Driver Option : Sumake, Uryu, M&L (Air Screwdriver) or Sumake, Kilews Electric, Delvo (Electric Screwdriver)

Available Screw Chart

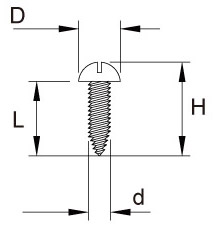

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

⚠ Special specification screws not listed in this table may also be compatible. For further information, please contact our service personnel.

| Pan Head Round Head | Flat Head Oval Head | Binding Head | Truss Head | Max. L Dimension (L) | ||||

|---|---|---|---|---|---|---|---|---|

| Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | |

| 4.6 | 8 | 4.9 | 8 | 5.2 | 9 | 12 | ||

| 4.5 | 8 | 5.0 | 8 | 5.3 | 8 | 5.7 | 10 | 16 |

| 5.5 | 9 | 6.0 | 9 | 6.3 | 9 | 6.9 | 11 | 20 |

| 6.0 | 9 | 7.0 | 10 | 7.3 | 10 | 8.1 | 12 | 22 |

| 7.0 | 10 | 8.0 | 11 | 8.3 | 11 | 9.4 | 13 | 22 |

| 8.0 | 11 | 9.0 | 12 | 9.3 | 12 | 10.6 | 14 | 22 |

| 9.0 | 12 | 10.0 | 13 | 10.3 | 13 | 11.8 | 15 | 22 |

| 10.5 | 13 | |||||||

Screwdriver Optional

The choice of screwdriver plays a critical role in fastening quality and operational efficiency.

We offer a curated selection of high-performance brands, including URYU, SUMAKE, and M&L torque-controlled pneumatic screwdrivers, as well as SUMAKE, KILEWS, and Delvo torque-controlled electric screwdrivers—providing flexibility to suit diverse application needs.

⚠ Note:

The torque values listed are provided by the screwdriver manufacturers and are based on test results measured using torque testers. Actual torque output during application may vary depending on the material, screw type, and fastening conditions.

▷ Compatibility Notice:

Other brands and specifications may also be supported, subject to project-based evaluation for integration feasibility.

- Gallerys

- Related Products

Fasten Stroke Cylinder Equipment

TM-6

The SEALS Fasten Stroke Cylinder Equipment integrates a pneumatic screwdriver module onto a cylinder-driven slide system. Activated via automatic control, foot switch, or foot valve, it enables smooth, hands-free screw fastening. Operators simply place the workpiece into the fixture, and the system completes the fastening process efficiently, accurately, and with consistent quality—ideal for reducing manual workload and enhancing production stability.

Torque Reaction Arm ( 505mm working radius)

TR-350

Seals TR-350 Torque Reaction Arm has a 505mm work radius from the spindle base. With 365 degree rotation, TR-350 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-350A is for pneumatic tools only. And, TR-350AE is both for electric and pneumatic screwdriver.

Torque Linear Arm ( 182-561mm working radius)

TA-300S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loadsAfter clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1122mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws.This Torque Reaction Arm can effectively reduce the space requirement of the workplace.With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment.It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.