Single Axis Automatic Screw Feeding

CM-100

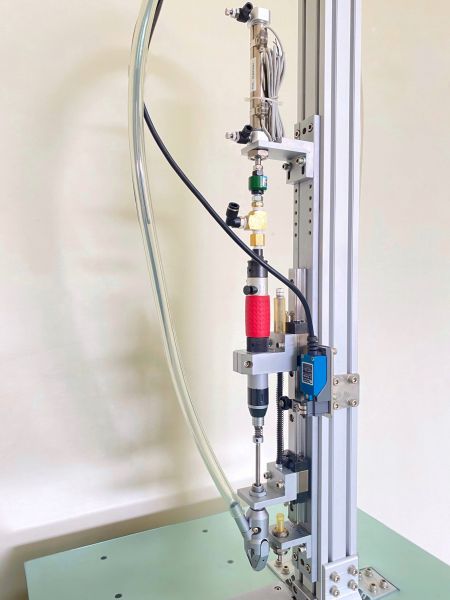

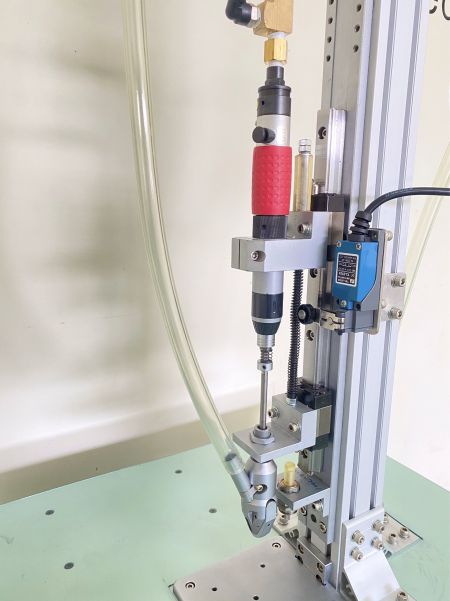

The SEALS CM-100 is engineered to improve assembly quality and reduce operator workload. Simply load the workpiece and tap the foot switch—the system automatically completes the screw fastening cycle.

Once aligned, the CM-100 performs screw ejection, tightening, re-feeding, and signal feedback within 1–2 seconds (actual time may vary depending on screw length, pitch, screwdriver speed, and whether it’s self-tapping). The entire fastening process is machine-controlled, ensuring precise torque and stable fastening quality.

Designed for easy integration with a compact structure and single-cylinder control, the CM-100 fits seamlessly into semi-automated stations or full production lines. It features intelligent screw feeding, fast response, and simplified operation—making it a reliable solution for boosting productivity and consistency.

Features

1. Automatic screw feeding eliminates manual screw handling.

2. Pneumatic torque-controlled screwdriver ensures fastening quality.

3. Smart feeding system conserves energy and prevents shortages.

4. Push-to-lock design avoids contact with the product surface, preventing stress or abrasion.

5. Equipped with extruded aluminum stand for excellent vertical alignment and fast height adjustment.

6. Foot switch for simple and intuitive operation.

7. Economical control box included.

8. Operator only needs to load/unload the part—no effortful screwing required.

Function

《30F》Specification

《30F》Specification 《501F》Specification

Voltage:220V、Single Phase Voltage:220V、Single Phase

Air Pressure:5.5 kg / cm² / 85PSI Air Pressure:5.5 kg / cm² / 85PSI

L / W / H:35 / 25 / 38 cm L / W / H:35 / 25 / 38 cm

Capacity:30 pcs/min. Capacity:50 pcs/min.

——Choose Feeder according to your needs——

- Dimensions

- Gallerys

- Related Products

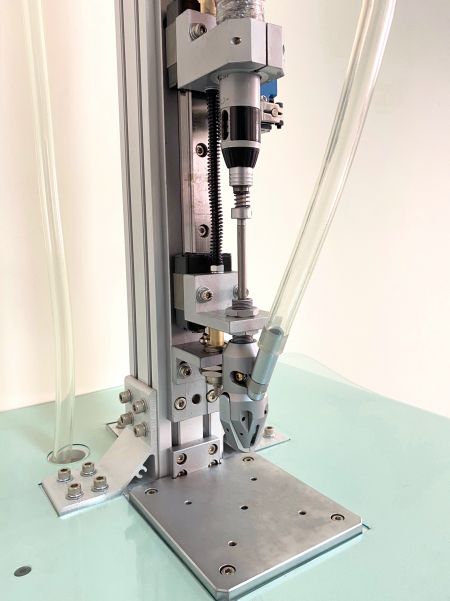

Spindle Type Automatic Screw Feeding Module by one cylinder

CM-100L

The SEALS CM-100L is a compact and cost-effective spindle-type screw fastening module designed for seamless integration into fully or semi-automated production lines. Featuring a single-cylinder design, it is ideal for applications with limited installation space or narrow screw pitch requirements—as tight as 45mm between screw holes.Compared to models like CM-100S and CM-100G, the CM-100L offers a simplified structure that reduces system cost while maintaining reliable performance. It supports both flat-surface and deep-hole screw fastening, with two standard cylinder stroke options to accommodate different assembly needs.Equipped with a push-to-start pneumatic torque-controlled screwdriver, this module ensures consistent fastening quality. Its compact design enables side-by-side installation in multi-axis setups. Durable, precise, and easy to integrate, the CM-100L is an excellent solution for enhancing automation efficiency in modern assembly systems.

Spindle Type Automatic Screw Fastening Module

CM-100R

The SEALS CM-100R is a spindle-type automatic screw fastening module designed for seamless integration with 6-axis robot arms, SCARA robots, XY tables, gantry systems, and other automated platforms. With standardized interface plates, the module can be quickly mounted onto various automation setups.Once aligned to the screw hole, the CM-100R performs screw pushing, fastening, re-feeding, and signal feedback within 1–2 seconds. (Actual cycle time may vary depending on screw size, pitch, driver speed, and whether the screw is self-tapping.)Equipped with multiple smart sensors, the CM-100R enables real-time status monitoring and precise control through the host system. Chengmao also offers weight estimation to ensure compatibility with robotic payload requirements.Fully pre-integrated with essential components—including screw jaws, pneumatic or electric screwdriver, torque detection, slide unit, screw feeder, cable routing, and signal interface—the CM-100R minimizes engineering time and accelerates deployment.The module can be used as a standalone unit or combined in multiple-unit configurations. With smart hose management, it supports operations from multiple angles, making it ideal for both fully automated and semi-automated assembly environments.

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Vibration Bowl Type Automatic Screw Feeder

CM-501

The SEALS CM-501 vibration bowl type automatic screw feeder is designed for speed, stability, and convenience. With a maximum feeding rate of 50 screws per minute, it significantly improves fastening efficiency in production environments.The system supports a wide range of screw sizes, from M1.0 to M8, and screw lengths up to 30 mm. Compared to sword-type feeders, the vibration bowl design provides a larger screw capacity due to its built-in tank, making it suitable for long-duration operations with fewer refills.Integrated with a pneumatic or electric torque-controlled screwdriver and a custom precision jig, the CM-501 offers stable, reliable fastening performance across various applications such as electronics, aluminum products, plastic components, and hardware assemblies.Its simplified mechanical structure allows for easier maintenance and long-term operational stability. The jig and feeding configuration can also be customized to match specific screw dimensions and workpiece requirements.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.