Automatic Screw Feeder with servo nut runner

CM-30T-SERVO

The SEALS CM-30T-SERVO adopts a high-precision, low-reaction-force servo nut runner that delivers detailed fastening data for every screw, ensuring speed, stability, and process transparency. When fastening parameters deviate from preset values, the system provides real-time alerts and generates a complete, traceable report to support quality control and auditing.

This system supports multi-step fastening actions programmed into a single job—ideal for complex tasks that conventional electric screwdrivers cannot perform. Additionally, it allows precise control of rotation angle and speed to meet specific tightening requirements.

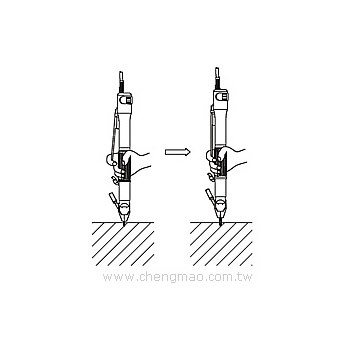

The screw jaw is custom-built based on the screw type and working environment, ensuring reliable positioning and stable operation. The lever-activated design meets ergonomic and labor-saving standards; the screwdriver automatically initiates fastening with a single press of the lever.

When paired with the TA-300 torque reaction arm, the tool maintains a stable vertical alignment, improves torque accuracy, and reduces operator fatigue. This setup is especially effective for high-torque shut-off applications where consistent torque control is essential.

Nickname

Automatic Screw Feeding Machine with servo nut runner

Features

1. Ergonomic lever-activated design for effortless operation.

2. Press the lever and the fastening process completes automatically.

3. Automatic feeding eliminates manual screw picking and positioning.

4. Suitable for 2.5mm ~ 6.0mm screws.

5. Fast operation speed: 20–30 screws per minute.

6. Torque-controlled screwdriver ensures fastening consistency.

7. Uses high-quality Japanese electric/pneumatic screwdrivers.

8. Intelligent fiber optic-controlled feeder saves power and avoids material shortage.

9. The bit automatically pushes screws without contact between the jaw and product surface, avoiding scratches and stress.

10. Equipped with a spring balancer for weight-free handling.

11. Compatible with multiple accessories such as TR-350A, TR-650AE, TA-600, THA, etc., for flexible configuration based on your needs.

Specification

- Voltage: 220V, Single Phase

- Air Pressure: 5.5 kg / cm² / 85PSI

- L / W / H: 35 / 25 / 38 cm

- Net Weight / Gross Weight: 23 kg / 31 kg

- Capacity: 30 pcs/min.

- Torque: Refer to screwdriver capacity

- Volume: M3 x 15 2000 pcs

- Driver: Estic branded Nut Runnerr

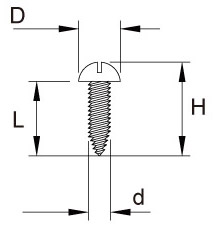

Available Screw Chart

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

⚠ Special specification screws not listed in this table may also be compatible. For further information, please contact our service personnel.

| Pan Head Round Head | Flat Head Oval Head | Binding Head | Truss Head | Max. L Dimension (L) | ||||

|---|---|---|---|---|---|---|---|---|

| Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | |

| 4.6 | 8 | 4.9 | 8 | 5.2 | 9 | 12 | ||

| 4.5 | 8 | 5.0 | 8 | 5.3 | 8 | 5.7 | 10 | 16 |

| 5.5 | 9 | 6.0 | 9 | 6.3 | 9 | 6.9 | 11 | 20 |

| 6.0 | 9 | 7.0 | 10 | 7.3 | 10 | 8.1 | 12 | 22 |

| 7.0 | 10 | 8.0 | 11 | 8.3 | 11 | 9.4 | 13 | 22 |

| 8.0 | 11 | 9.0 | 12 | 9.3 | 12 | 10.6 | 14 | 22 |

| 9.0 | 12 | 10.0 | 13 | 10.3 | 13 | 11.8 | 15 | 22 |

| 10.5 | 13 | |||||||

Accessory

Extension Hopper: Part No. RH-1 (Optional)

- Gallerys

- Related Products

Automatic Screw Feeder with Lever-Activating screwdriver set

CM-30T

SEALS CM-30T Automatic Screw Feeder adopt ergonomic design of screwdriver set. The operator only need to simply trigger the lever of driver and the bit will push downward and fasten screw automatically. SEALS CM-30T reduces the downward press stroke of operator to enhance the productivity and reduce fatige . Meanwhile, the jaw will not press the surface of work-piece hardly so that it could also protect the coating of products. For automation purpose, SEALS automatic screw feeder also could be integrated into automation machine such as XY Table, SCARA robot, 6 axis ROBOT and any customized auto assembly machine, etc. And, its automation version also can provide relevant signals and receive control signal for communicate with major control system.

Torque Linear Arm ( 182-561mm working radius)

TA-300S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loadsAfter clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1122mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws.This Torque Reaction Arm can effectively reduce the space requirement of the workplace.With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment.It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

Torque Linear Arm ( 236-744mm working radius)

TA-600S

Seals Torque Reaction Arm is designed to avoid repetitive work and excessive use of arm injuries in daily work. We provide Torque Reaction Arm to improve the ergonomic manufacturing process to eliminate instant torque and weight loadsAfter clamping the screwdriver, the Torque Reaction Arm can be operated back and forth, left and right, up and down, and can rotate freely at 360°. It can always support the screwdriver. The maximum working diameter is 1488mm. Various screw locking operations can be carried out within the range to reduce work The failure rate ensures that the screwdriver locks the screws at a vertical angle, improves the quality of screw locking, and reduces product quality problems such as operator errors and defective locking screws.This Torque Reaction Arm can effectively reduce the space requirement of the workplace.With the help of the spring lifting force of the Spring Balancer, the suspended arm frame is in a weightless state, which reduces the labor status of personnel, improves labor production efficiency, and creates a safe and efficient working environment.It can be directly fixed on the work surface (recommended) and a C-shaped table clamp is provided, two installation methods.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.