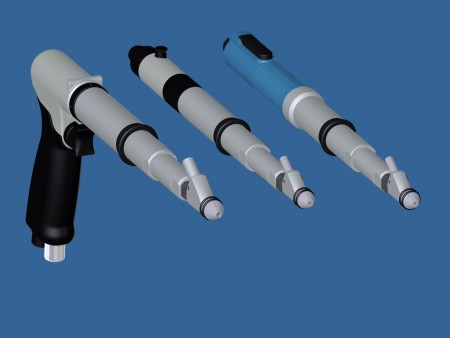

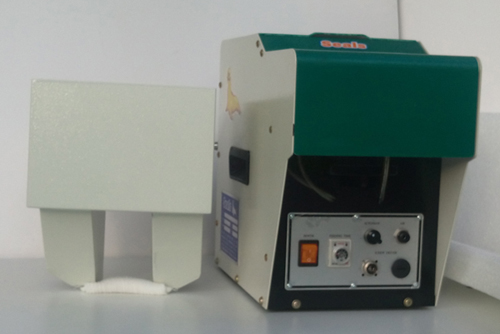

Automatic Screw Feeder with telescope screwdriver set

CM-40

The SEALS CM-40 Automatic Screw Feeder is designed for speed, stability, and convenience. It integrates high-precision jaws, a reliable automatic feeding system, and Japanese-made torque-controlled pneumatic or electric screwdrivers to significantly enhance screw fastening speed and production efficiency.

The screw jaws are custom-designed based on the customer's screw type and working environment, ensuring smooth and stable operation. SEALS also provides screwdriver model recommendations tailored to your specific screw and workpiece characteristics to ensure optimal fastening results.

The material hopper adopts an up-and-down pushing board design to minimize screw surface scratches and keep feeding noise to a minimum. Combined with a fiber optic control system, the feeder intelligently stops when the chute is full, saving power and further reducing noise.

The air blow feeding mechanism enables the next screw to be delivered to the jaw within 0.5 seconds—often before the operator moves to the next fastening point—greatly improving cycle time. A horizontal vibration chute is available to improve feeding performance for lightweight screws, painted screws, or screws with washers.

The telescope-type screwdriver delivers consistent downward force directly into the sleeve of the screw, making it particularly suitable for self-tapping screws and wood screws.

For automation integration, the screw feeder can be triggered via a dry contact to blow one screw per cycle. The screwdriver can also be mounted on a cylinder to enable vertical fastening strokes in fully automated assembly systems.

Nickname

Automatic Screw Fastening Feeder

Features

1. Designed for speed, stability, and user-friendliness with integrated pneumatic/electric screwdrivers, auto screw feeders, and precision jaws to boost productivity.

2. Custom-designed jaws based on actual screws and working conditions for stable performance.

3. Automatic feeding eliminates manual screw handling and improves workflow efficiency.

4. Supports screw sizes from 2.5mm to 6.0mm.

5. Operating speed reaches 20–30 screws per minute.

6. Torque-controlled screwdriver ensures consistent fastening quality.

7. Equipped with high-quality Japanese electric/pneumatic screwdrivers.

8. Intelligent feeding system helps save energy and prevent screw shortages.

9. Includes a spring balancer for weight-free manual operation.

10. Compatible with TR-350A, TR-350AE, TR-650A, TR-650AE, TA-300, TA-600, TM-6, THA, and THB accessories for enhanced performance and flexible integration.

Specification

- Voltage: 220V, Single Phase

- Air Pressure: 5.5 kg / cm² / 85PSI

- L / W / H: 45 / 24 / 39 cm

- Net Weight / Gross Weight: 26 kg / 35 kg

- Capacity: 30 pcs/min.

- Torque: Refer to screwdriver capacity

- Volume: M3 x 15 2000 pcs

- Driver Option : Sumake, Uryu, M&L (Air Screwdriver) or Sumake, Kilews Electric, Delvo (Electric Screwdriver)

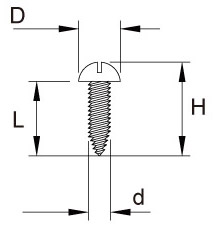

Available Screw Chart

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

⚠ Special specification screws not listed in this table may also be compatible. For further information, please contact our service personnel.

| Pan Head Round Head | Flat Head Oval Head | Binding Head | Truss Head | Max. L Dimension (L) | ||||

|---|---|---|---|---|---|---|---|---|

| Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | Screw Head Dia. (D) | Min. H Dimension (H) | |

| 4.6 | 8 | 4.9 | 8 | 5.2 | 9 | 12 | ||

| 4.5 | 8 | 5.0 | 8 | 5.3 | 8 | 5.7 | 10 | 16 |

| 5.5 | 9 | 6.0 | 9 | 6.3 | 9 | 6.9 | 11 | 20 |

| 6.0 | 9 | 7.0 | 10 | 7.3 | 10 | 8.1 | 12 | 22 |

| 7.0 | 10 | 8.0 | 11 | 8.3 | 11 | 9.4 | 13 | 22 |

| 8.0 | 11 | 9.0 | 12 | 9.3 | 12 | 10.6 | 14 | 22 |

| 9.0 | 12 | 10.0 | 13 | 10.3 | 13 | 11.8 | 15 | 22 |

| 10.5 | 13 | |||||||

Screwdriver Optional

The choice of screwdriver plays a critical role in fastening quality and operational efficiency.

We offer a curated selection of high-performance brands, including URYU, SUMAKE, and M&L torque-controlled pneumatic screwdrivers, as well as SUMAKE, KILEWS, and Delvo torque-controlled electric screwdrivers—providing flexibility to suit diverse application needs.

⚠ Note:

The torque values listed are provided by the screwdriver manufacturers and are based on test results measured using torque testers. Actual torque output during application may vary depending on the material, screw type, and fastening conditions.

▷ Compatibility Notice:

Other brands and specifications may also be supported, subject to project-based evaluation for integration feasibility.

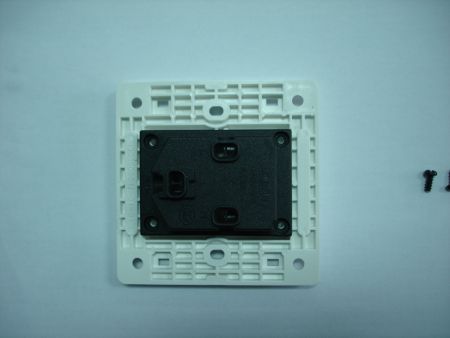

Accessory

Extension Hopper: Part No. RH-3 (Optional)

- Gallerys

- Movies

- Related Products

Torque Reaction Arm ( 505mm working radius)

TR-350

Seals TR-350 Torque Reaction Arm has a 505mm work radius from the spindle base. With 365 degree rotation, TR-350 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-350A is for pneumatic tools only. And, TR-350AE is both for electric and pneumatic screwdriver.

Torque Reaction Arm ( 750mm working radius)

TR-650

Seals TR-650 Torque Reaction Arm has a 750mm work radius from the spindle base. With 365 degree rotation, TR-650 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-650A is for pneumatic tools only. And, TR-650AE is both for electric and pneumatic screwdriver.

Fasten Stroke Cylinder Equipment

TM-6

The SEALS Fasten Stroke Cylinder Equipment integrates a pneumatic screwdriver module onto a cylinder-driven slide system. Activated via automatic control, foot switch, or foot valve, it enables smooth, hands-free screw fastening. Operators simply place the workpiece into the fixture, and the system completes the fastening process efficiently, accurately, and with consistent quality—ideal for reducing manual workload and enhancing production stability.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.