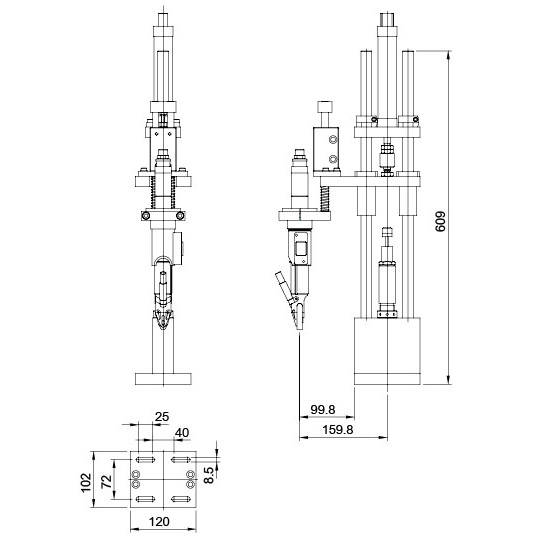

Fasten Stroke Cylinder Equipment

TM-6

The SEALS Fasten Stroke Cylinder Equipment integrates a pneumatic screwdriver module onto a cylinder-driven slide system. Activated via automatic control, foot switch, or foot valve, it enables smooth, hands-free screw fastening. Operators simply place the workpiece into the fixture, and the system completes the fastening process efficiently, accurately, and with consistent quality—ideal for reducing manual workload and enhancing production stability.

Nickname

Automatic Screw Fastening Cylinder Unit

Features

1. Pneumatic cylinder drives the screwdriver module vertically to perform fast and precise screw fastening.

2. Compatible with foot valve or foot switch for hands-free and easy operation.

3. Standard cylinder stroke of 150mm; customizable upon request.

4. Can be integrated with positioning jigs to improve fastening accuracy and stability.

5. Supports both standard and torque-controlled pneumatic screwdrivers for various quality demands.

6. Modular design allows for easy maintenance and quick replacement of consumables.

7. Ideal for semi-automated workstations to enhance efficiency and ensure consistent quality.

8. Suitable for small to medium-sized products requiring repetitive, torque-sensitive, or depth-controlled fastening.

9. Customizable control logic such as dual-speed descent or sensor-activated triggers can be implemented.

10. Reduces operator fatigue and error, improving overall line stability and productivity.

Function

- Dimensions

- Movies

- Related Products

Automatic Screw Feeder with telescope screwdriver set

CM-30

SEALS Automatic Screw Feeder, CM-30, could keep the low noise and less scratch of screw surface in material hopper due to its up-and-down pushing board design. With Fiber Optic control, it also reduce noisy and saving power while it is full in chute. By the air blow feeding system, you can get the next screw within 0.5 second in jaw before you move to the next fasten position. No need to pick screw, no need to put screw into drive bit and prevent rust due to hand sweating. Meanwhile, the telescope type screwdriver set deliver the downward force into the sleeve of screw. It is quite essential for self tapping screw and wood screw. For automation integration, the screw feeder can be control to air blowing one screw by giving a dry contact. And, the screwdriver also can be installed into a cylinder for fastening stroke action in fully automation assembly line.

Automatic Screw Feeder with telescope screwdriver set

CM-40

The SEALS CM-40 Automatic Screw Feeder is designed for speed, stability, and convenience. It integrates high-precision jaws, a reliable automatic feeding system, and Japanese-made torque-controlled pneumatic or electric screwdrivers to significantly enhance screw fastening speed and production efficiency.The screw jaws are custom-designed based on the customer's screw type and working environment, ensuring smooth and stable operation. SEALS also provides screwdriver model recommendations tailored to your specific screw and workpiece characteristics to ensure optimal fastening results.The material hopper adopts an up-and-down pushing board design to minimize screw surface scratches and keep feeding noise to a minimum. Combined with a fiber optic control system, the feeder intelligently stops when the chute is full, saving power and further reducing noise.The air blow feeding mechanism enables the next screw to be delivered to the jaw within 0.5 seconds—often before the operator moves to the next fastening point—greatly improving cycle time. A horizontal vibration chute is available to improve feeding performance for lightweight screws, painted screws, or screws with washers.The telescope-type screwdriver delivers consistent downward force directly into the sleeve of the screw, making it particularly suitable for self-tapping screws and wood screws.For automation integration, the screw feeder can be triggered via a dry contact to blow one screw per cycle. The screwdriver can also be mounted on a cylinder to enable vertical fastening strokes in fully automated assembly systems.

Vibration Bowl Type Automatic Screw Feeder

CM-501

The SEALS CM-501 vibration bowl type automatic screw feeder is designed for speed, stability, and convenience. With a maximum feeding rate of 50 screws per minute, it significantly improves fastening efficiency in production environments.The system supports a wide range of screw sizes, from M1.0 to M8, and screw lengths up to 30 mm. Compared to sword-type feeders, the vibration bowl design provides a larger screw capacity due to its built-in tank, making it suitable for long-duration operations with fewer refills.Integrated with a pneumatic or electric torque-controlled screwdriver and a custom precision jig, the CM-501 offers stable, reliable fastening performance across various applications such as electronics, aluminum products, plastic components, and hardware assemblies.Its simplified mechanical structure allows for easier maintenance and long-term operational stability. The jig and feeding configuration can also be customized to match specific screw dimensions and workpiece requirements.

Vibration Bowl Type Automatic Screw Feeder for Two Screwdriver Sets

CM-502

The SEALS CM-502 Vibration Bowl Type Automatic Screw Feeder is designed for speed, stability, and convenience. It combines a high-performance vibration bowl feeder, precision-engineered screw jaws, and pneumatic or electric torque screwdrivers to significantly enhance production efficiency.A single screw feeder unit is capable of supplying screws independently to two separate screwdriver sets. Each channel operates with its own control system, allowing two operators to work simultaneously at different speeds. This flexible design supports up to 45 screws per minute per channel, effectively reducing labor time and unit cost.The vibration bowl is compatible with screw sizes ranging from M1.0 to M8 and screw lengths up to 30 mm, making it suitable for a wide variety of fastening applications. Compared to sword-type feeders, the vibration bowl offers a larger screw capacity and more stable feeding.With a simplified mechanical structure, the CM-502 is easy to maintain, reducing downtime and ensuring long-term operational stability.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.