Magnetic Type Automatic Screw Feeding Machine

CM-20M

The CM-20M is a handheld automatic screw fastening solution that integrates vibratory screw alignment, air-blow screw feeding, and trigger-activated fastening operation. This configuration allows operators to maintain a stable cycle time even when working at mobile stations or in multi-angle fastening applications.

After alignment, screws are delivered to the fastening point via air-blow feeding and positioned by a magnetic driver bit, ensuring stable alignment and improved positioning accuracy during the initial fastening stage.

During operation, the operator simply pulls the trigger, causing the driver bit to advance the screw and complete the fastening process. Since this fastening method does not require the front sleeve or fixture to press against the workpiece surface, it effectively reduces the risk of scratches or surface marks. This makes the CM-20M especially suitable for cosmetic parts, painted components, anodized surfaces, or products with surface protection requirements.

It should be noted that the positioning mechanism of the CM-20M relies on the driver bit’s ability to hold the screw magnetically. Therefore, only screws with magnetic properties are applicable. For non-magnetic screw materials—such as most stainless-steel screws—a push-down type fastening model without magnetic dependency is recommended to ensure stable feeding and fastening performance.

Nickname

Hand-held adsorption automatic locking screw machine

The CM-20M is a handheld automatic screw fastening solution that integrates vibratory screw alignment, air-blow screw feeding, and trigger-activated fastening operation, allowing operators to maintain a stable cycle time even at mobile stations or in multi-angle fastening applications.

After alignment, screws are delivered to the fastening point via air-blow feeding and positioned and held by a magnetic driver bit, improving alignment stability during the initial fastening stage.

During fastening, the operator pulls the trigger, causing the driver bit to advance the screw and complete the fastening operation. As this fastening method does not require the front sleeve to press against the workpiece surface, it effectively reduces the risk of scratches, pressure marks, or other surface damage. This makes the CM-20M particularly suitable for cosmetic parts, painted components, anodized surfaces, or products with surface protection requirements.

It should be noted that the positioning mechanism of the CM-20M relies on the driver bit holding the screw magnetically. Therefore, it is only applicable to screws with magnetic properties. For non-magnetic screw materials (such as most stainless-steel screws), a push-down type fastening model without magnetic dependency is recommended to ensure stable feeding and fastening performance.

Features

◎ Trigger-Activated, Handheld Operation

Fastening is initiated by pulling the trigger, offering flexible handling. This design is suitable for workstations that require fine position adjustments or multi-angle fastening.

◎ Non-Contact Fastening Design

During fastening, the front sleeve does not need to contact the workpiece surface, reducing the risk of cosmetic defects or surface damage.

◎ Magnetic Screw Positioning

The driver bit holds the screw magnetically, improving alignment stability during the initial fastening stage.

◎ Torque-Based Feeding Control

The system advances the next screw only after fastening is completed and a valid torque signal is received, ensuring consistent fastening quality.

◎ Screw / Workpiece Counting Management

Supports air-blow counting and torque-based counting, and can be combined with workpiece counting to facilitate production quality and output control.

Specification

- Power Supply: 110V / 220V

- Operating Air Pressure: 0.5–0.7 MPa

- Dimensions (L × W × H): 333.15 × 200 × 299.2 mm

- Feeding Speed: Approx. 0.7 seconds per screw

- Torque: Depends on the selected screwdriver specification

- Capacity: Approx. 1,600 screws (M3 × 8)

- Feeding Distance: 1–3 m

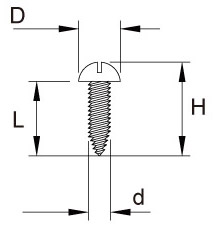

Available Screw Chart

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

⚠ Special specification screws not listed in this table may also be compatible. For further information, please contact our service personnel.

| Head Diameter(D) | Applicable Overall Screw Length(H) | Remarks | ||||||

| 3.5 | 8~12 | 1、Limited to Phillips, Pozidriv, Torx, and Hex socket screw types. 2、Applicable thread diameter: M2–M5. 3、The drive recess must be centered on the screw head. 4、If the screw length exceeds this range, custom evaluation is available upon request. | ||||||

| 4 | ||||||||

| 5 | ||||||||

| 6 | 9~13 | |||||||

| 7 | 10~14 | |||||||

| 8 | 12~16 | |||||||

- Related Products

Robot Type Vacuum Pick-up Automatic Screw Feeder

CM-TABLE-V

The CM-TABLE-V system integrates a Japan-made Quicher screw presenter with a programmable XY desktop robot for automatic vacuum screw pick-up and placement. Screws are lined up and rotated to the vacuum pick-up point, where the nozzle collects and delivers them to each fastening position according to programmed paths.The system is ideal for automated screw fastening where operators only need to load/unload the workpieces, as the robot handles the entire screw fastening cycle. The vacuum nozzle and clamping system can be customized based on screw type and working conditions for consistent, stable operation.Equipped with a brushless torque-controlled screwdriver, the system can detect floating screws, stripped threads, and torque completion, ensuring fastening quality. The belt-driven stepper motor ensures low noise and high positioning accuracy (±0.02mm).

Gantry Type XY Table Automatic Screw Fastening Machine

CM-TABLE-GANTRY

The SEALS CM-TABLE-GANTRY is a floor-standing automatic screw fastening system built with a robust gantry structure, featuring dual Y-axis supports and a ball screw-driven XY servo slide table. Compared to single-arm or cantilever robots, this design provides superior repeatability, higher load capacity, and greater structural stability—making it ideal for large-scale assemblies and multi-screw fastening applications.Integrated with SEALS air-blow screw feeding technology, the system delivers screws in as fast as 0.2 seconds per cycle. The high-precision XY servo module shortens travel distances by over 60%, significantly improving production speed and efficiency.Widely used in industries such as automotive components, computer peripherals, and large plastic or metal parts, the SEALS CM-TABLE-GANTRY supports multi-point fastening and can be optionally equipped with safety light curtains for enhanced operator protection.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.