Automatic Screw Feeder with telescope screwdriver set

CM-20

The CM-20 is a push-down type automatic screw fastening machine that integrates vibratory screw alignment, air-blow screw feeding, and an electric screwdriver system. It is designed for fixed workstations and repetitive fastening applications with stable cycle time.

During operation, the front sleeve comes into contact with the workpiece surface. Once downward pressure is applied and the preset stroke position is reached, the screwdriver is activated to perform the fastening process, allowing operators to achieve accurate fastening through a simple and intuitive push-down motion.

Fastening completion is determined by torque feedback from the screwdriver, and the system feeds the next screw only after proper tightening is confirmed. This control mechanism effectively prevents quality issues such as stripped threads, idle rotation, or misfeeding, making the CM-20 particularly suitable for mass-production assembly lines requiring consistent fastening quality and process stability.

Nickname

Automatic Screw Fastening Feeder

The CM-20 adopts a push-down type fastening design, in which the overall fastening process is carried out through the coordinated operation of three core systems: vibratory screw alignment, air-blow screw feeding, and electric screwdriver fastening.

After vibratory alignment, screws enter the feeding track and are stably delivered to the fastening point via air-blow feeding. Once the front sleeve is pressed down to contact the workpiece surface and reaches the preset stroke position, the electric screwdriver is activated to perform the fastening operation.

Upon completion of fastening, the system evaluates tightening status based on torque feedback signals from the electric screwdriver. The next screw is fed only after proper fastening is confirmed.

This control logic effectively prevents misfeeding caused by stripped threads, idle rotation, or incomplete fastening, thereby improving overall fastening consistency and quality stability.

As the front sleeve comes into contact with the workpiece surface during fastening, the CM-20 is particularly suitable for applications where surface contact is not strictly restricted. It provides stable operation while offering an intuitive and easy-to-learn user experience.

Features

◎ Push-Down Activated Fastening Mechanism

Fastening is initiated by downward pressure applied through the front sleeve, resulting in a simple and intuitive operation. This design is ideal for standardized workstations and long-duration repetitive fastening tasks.

◎ Air-Blow Automatic Screw Feeding Design

After vibratory alignment, screws are delivered to the fastening point via air-blow feeding, reducing manual screw handling and improving overall operational efficiency.

◎ Torque-Based Feeding Control Logic

The system advances the next screw only after a valid torque signal is received from the electric screwdriver, effectively preventing incomplete fastening.

◎ Screw / Workpiece Counting Functions

Supports air-blow counting and torque-based counting, with configurable screw quantity per workpiece, facilitating production management and quality traceability.

◎ Modular Structure for Easy Adjustment and Maintenance

Interchangeable components can be configured according to different screw specifications, providing both application flexibility and maintenance convenience.

Specification

- Power Supply: 110V / 220V

- Operating Air Pressure: 0.5–0.7 MPa

- Dimensions (L × W × H): 333.15 × 200 × 299.2 mm

- Feeding Speed: Approx. 0.7 seconds per screw

- Torque: Depends on the selected screwdriver specification

- Capacity: Approx. 1,600 screws (M3 × 8)

- Feeding Distance: 1–3 m

Available Screw Chart

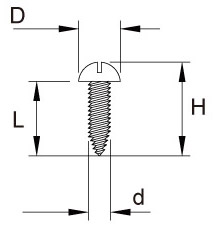

Listed below is the typical model of screw sizes that can be accepted for production. (Unit: mm)

⚠ Special specification screws not listed in this table may also be compatible. For further information, please contact our service personnel.

| Head Diameter(D) | Applicable Overall Screw Length(H) | Remarks | ||||||

| 3.5 | 8~12 | 1、Limited to Phillips, Pozidriv, Torx, and Hex socket screw types. 2、Applicable thread diameter: M2–M5. 3、The drive recess must be centered on the screw head. 4、If the screw length exceeds this range, custom evaluation is available upon request. | ||||||

| 4 | ||||||||

| 5 | ||||||||

| 6 | 9~13 | |||||||

| 7 | 10~14 | |||||||

| 8 | 12~16 | |||||||

- Related Products

Torque Reaction Arm ( 505mm working radius)

TR-350

Seals TR-350 Torque Reaction Arm has a 505mm work radius from the spindle base. With 365 degree rotation, TR-350 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-350A is for pneumatic tools only. And, TR-350AE is both for electric and pneumatic screwdriver.

Torque Reaction Arm ( 750mm working radius)

TR-650

Seals TR-650 Torque Reaction Arm has a 750mm work radius from the spindle base. With 365 degree rotation, TR-650 provides big work area. Meanwhile, its bendable arm design provide less conflict with other operator.TR-650A is for pneumatic tools only. And, TR-650AE is both for electric and pneumatic screwdriver.

Fasten Stroke Cylinder Equipment

TM-6

The SEALS Fasten Stroke Cylinder Equipment integrates a pneumatic screwdriver module onto a cylinder-driven slide system. Activated via automatic control, foot switch, or foot valve, it enables smooth, hands-free screw fastening. Operators simply place the workpiece into the fixture, and the system completes the fastening process efficiently, accurately, and with consistent quality—ideal for reducing manual workload and enhancing production stability.

- Files Download

Automatic Screw Feeder Catalog

Full information of production line of automatic screw feeder from SEALS. This includes models for portable and automation application to enhance your screw assembly ability, efficiency, quality.